It’s not too late for a rescue.

Failing validation?

Not achieving lot-to-lot consistency?

Told your design is “impossible”?

The problem may not be your design.

It may be your supplier.

Talk to MTD.

We are expert problem-solvers.

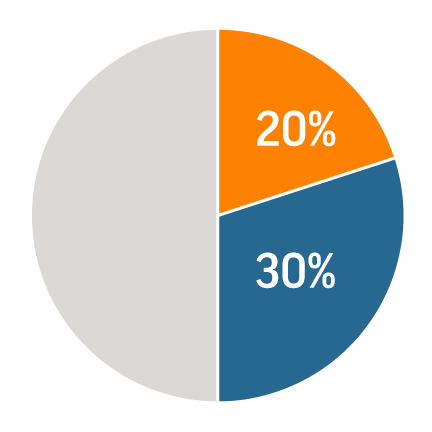

20% of our new projects come to us as “rescues,” or failed attempts by other suppliers.

Another 30% are projects that no one else would even attempt.

Check out our Rescue Stories:

From Failure to Validation

In jeopardy of missing a launch deadline, a major OEM turned to MTD for a new approach to successfully validate production for an asthma component.

Turning Impossible into Possible

How a seemingly minor design change and alternative material choice achieved higher yield, better quality and lower costs for a drug delivery system.

Finding Bioabsorbable Success

How the design was wrongfully blamed when a bioabsorbable part suffered from inconsistencies from lot to lot – and how MTD resolved it.

Keys to Bioabsorbable Process Development

How developing a custom tool was key to achieving control and consistency in IV loss – and successful proof of concept of a bioabsorbable fixation design.

Talk to us about your challenging project.

Why MTD?