Micro Metrology

Although each micro-manufacturing cell is considered autonomous, MTD must also depend on proper quality assurance techniques, which come in the form of micro metrology and testing.

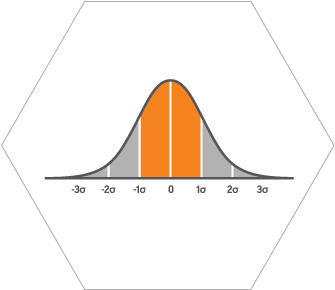

Custom fixturing and non-contact OGP measurement programs are created and validated in-house for each part. We also have in-house CT Scanning for part dimensions that are difficult to capture through standard methods. Measurement systems are validated for inspecting all critical dimensions with a passing Gage Repeatability and Reproducibility (Gage R&R) so there is high confidence that the data we provide to the customer is valid and captured with accuracy.

Goals of Gage R&R

- establish a measurement system that is capable of detecting dimensional defects

- provide evidence that multiple operators can use the measurement system interchangeably

- establish confidence internally and externally in the data collected and used in reporting process capability

At MTD, we achieve .001–.002″ tolerances every day. But passing a Gage R&R with these tolerances can be extremely difficult.

One statement of caution is that a Gage R&R does not tell you that the part is within specification. What is does tell you is that your measurement system can accurately and consistently measure your part.

Product Realization and In-House Testing

For example, MTD’s Product Realization methodology resembles what you would normally find in the industry, following a standard IQ/OQ/PQ (Installation/Operational/Performance Qualifications). But because of the typical part size and tight tolerances, we have adapted our processes and tools to focus on perfecting the measurement system early on in your project.

Along with dimensional testing, various other tests may be required to meet a part’s desired specification to provide evidence of successful form, fit, and function. Our in-house testing includes:

Thermal Testing

- Differential Scanning Calorimetry

- Melt Flow Index

- Moisture Content Analysis

Chemical Testing

- Inherent Viscosity

Mechanical Testing

- Tensile Testing

- Ultimate Elongation

- Custom Failure Testing

MTD has in-house CT scanning and several innovative fixtures, including our rotary fixture and even mirrors, to help measure parts without damaging them.