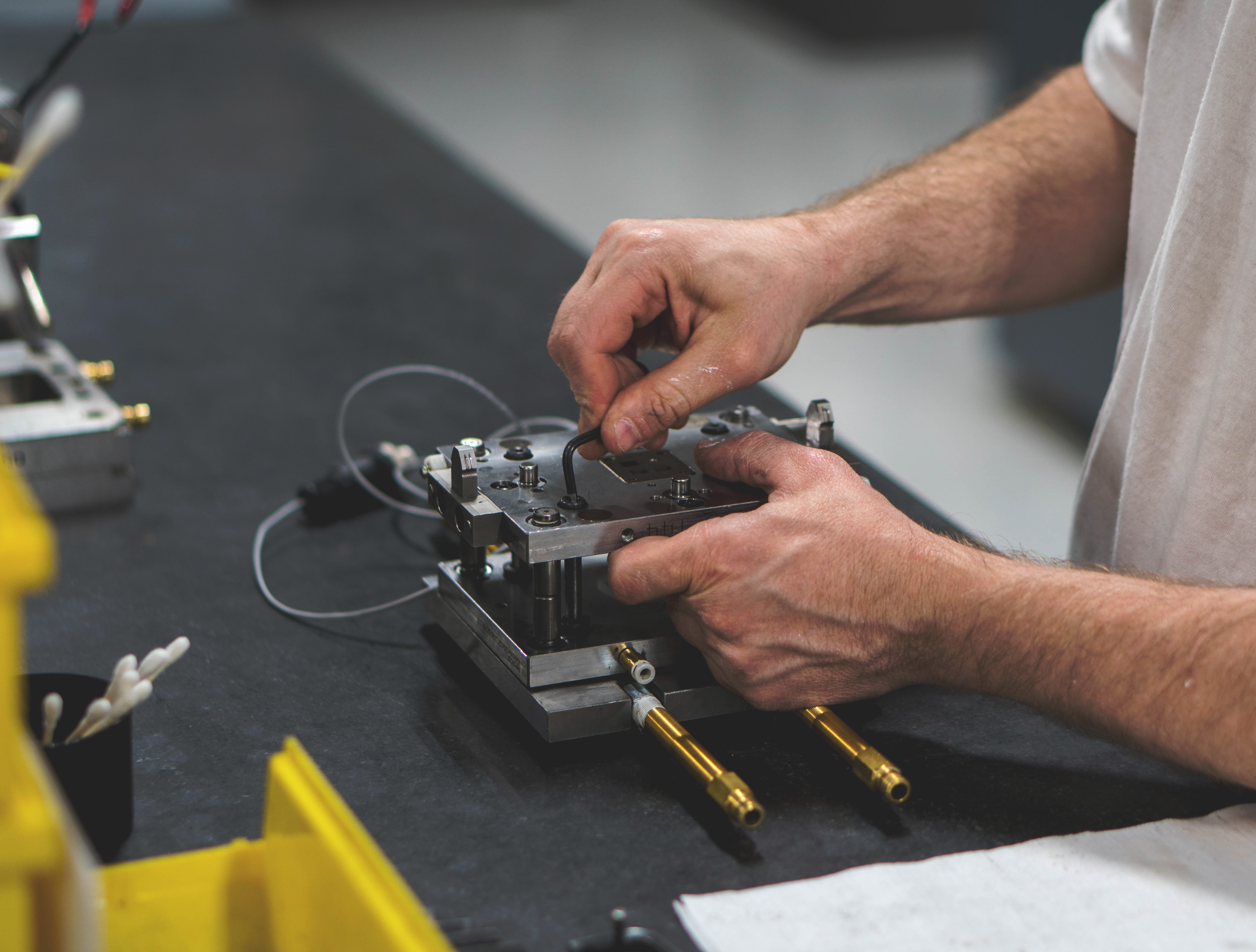

Micro Tooling

High resolution features created with ultra-precise tooling means superior products.

In-house tooling means a shorter, stronger development process.

MTD is globally known as a leader and premiere tooling shop for micro molds and it is because of our unique ability to create high resolution features as medical devices get smaller and smaller. When MTD receives a design, it is our responsibility to use every tool in our toolbox to design a mold and come up with a solution that provides a client that perfect match to their model.

At MTD, our workpiece accuracy target is 42 millionths. Workpiece accuracy refers to what the actual part comes out of the machine looking like, and not what the machine is specified to do. This is what separates MTD apart – exact tooling execution.

Our Sarix 3D EDM milling machine is a very unique piece of equipment that creates cavity geometry by following a tool path similar to CNC milling, but the major difference is that the end mill is actually an electrode that can be as small as 5 microns.

Micro Tooling vs. Macro Tooling: Learn the 5 key differences here

To be successful, there needs to be an intimate knowledge of the full manufacturing picture.

In-house design is required to keep communication flowing between all departments as tool makers, process engineers, and others all have upfront input that needs to be relayed quickly and concisely during the design phase.