Services • Micro Molding

Micro Injection Molding

Medical micro injection molding requires much more specialized equipment than traditional micro injection molding. In the medical device world, it’s often the smallest parts that carry the greatest importance relative to the functionality and safety of a medical device. More than ever, embracing the best proven processes and tools for manufacturing is critical to successful product development.

With advanced micro injection molding, it is possible to achieve successful validated production of complex components in a variety of medical grade plastics.

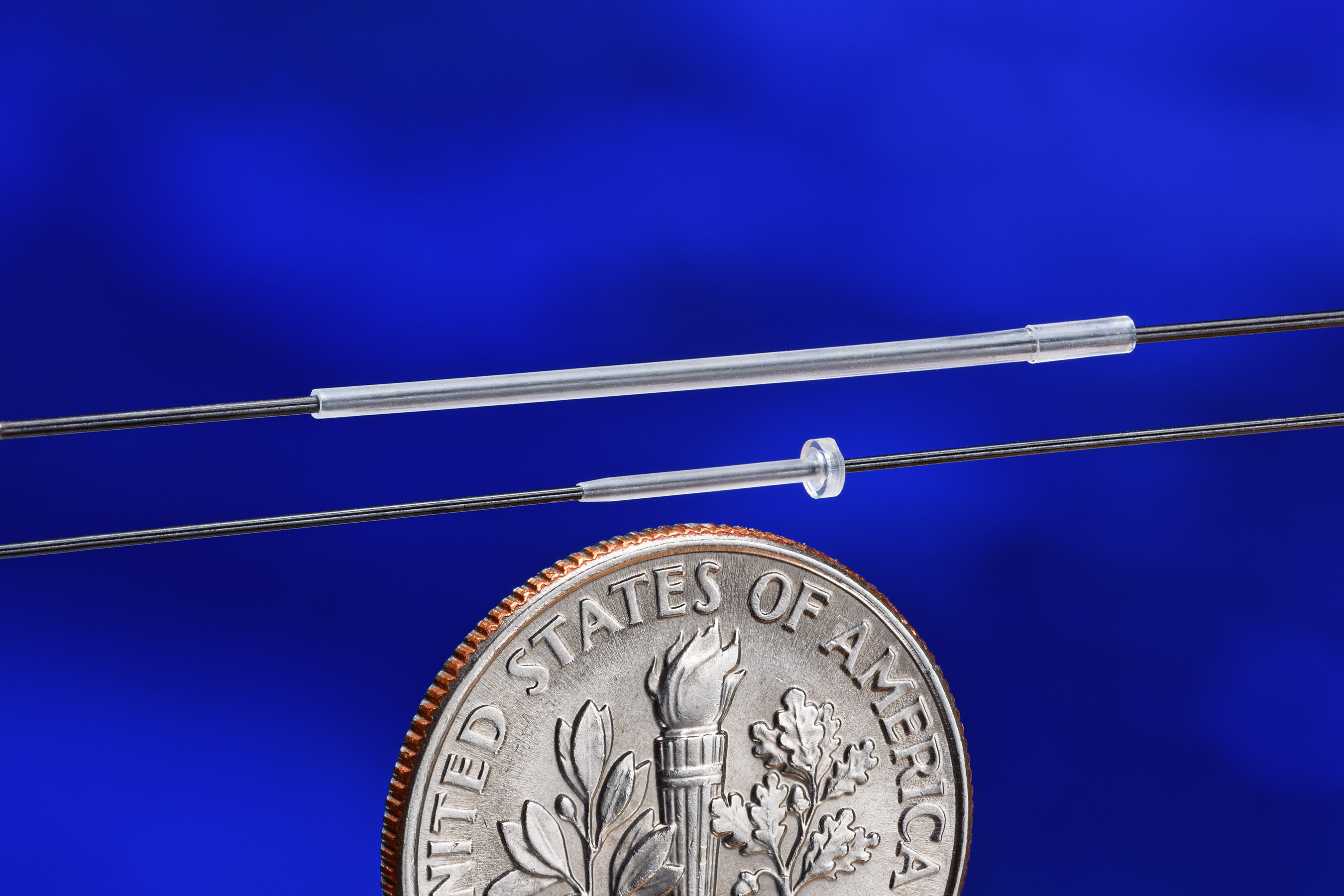

Drug Delivery Straw & Cannula

Precise long thin walls are possible with micro injection molding. This drug delivery straw (top) features a .005″ long thin-walled design made of polypropylene. The cannula (bottom) features walls as thin as .0025″.

Bioabsorbable Fixation Suture

This unique bioabsorbable design required an extremely challenging tooling approach and extremely tight tolerances throughout for part functionality that requires a balance of flexibility and rigidness.

Implantable Ligating Clip

This tiny clip features intricate micro features: a crescent-shaped window measuring 0.010″ (0.25 mm) wide, with an average cross section that’s 0.20″ (5.08 mm). And it snaps close!

Here are some of the key technology and special controls that are unique to advanced medical micro manufacturing:

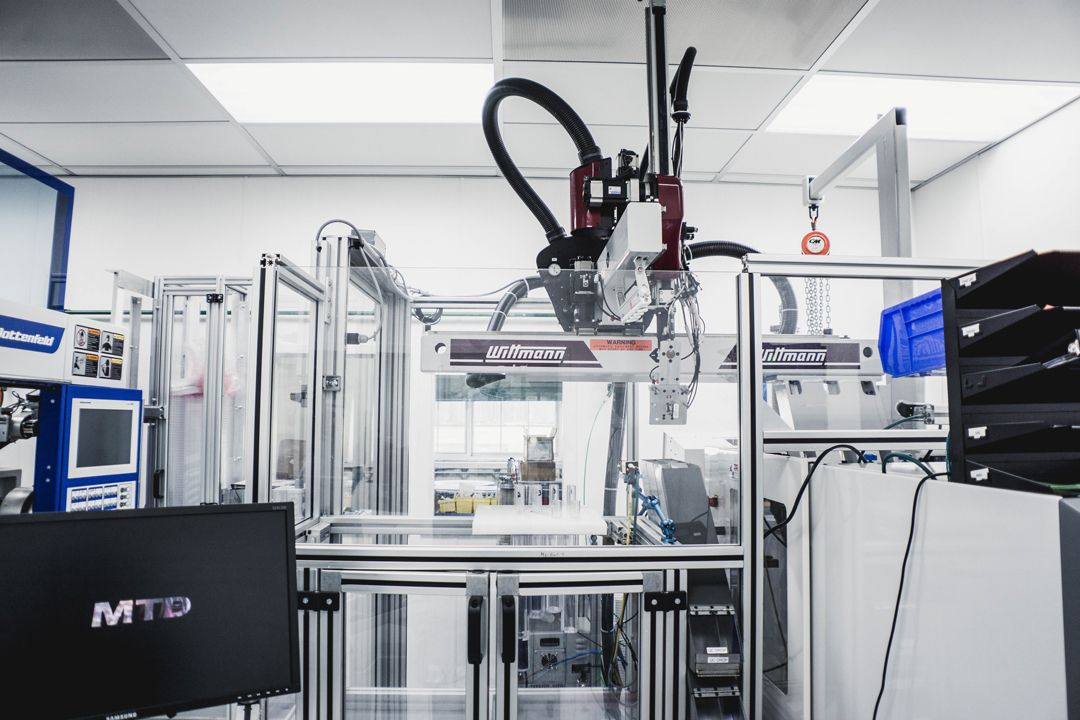

Utilizing Specialized Injection Molding Equipment

MTD has invested in and customized top-of-the-line equipment that is much more specialized than conventional micro injection. Among the many advantages of this advanced equipment is maximizing the efficiency for our process engineering team to develop the widest process window possible.

Dependable and accurate equipment is essential when working with such small numbers. As a matter of fact, our machines have plunger resolution of .03mm. That means that this small measurement—25% of the diameter of a human hair—on position is the difference between a full shot, short shot, or a flashed shot.

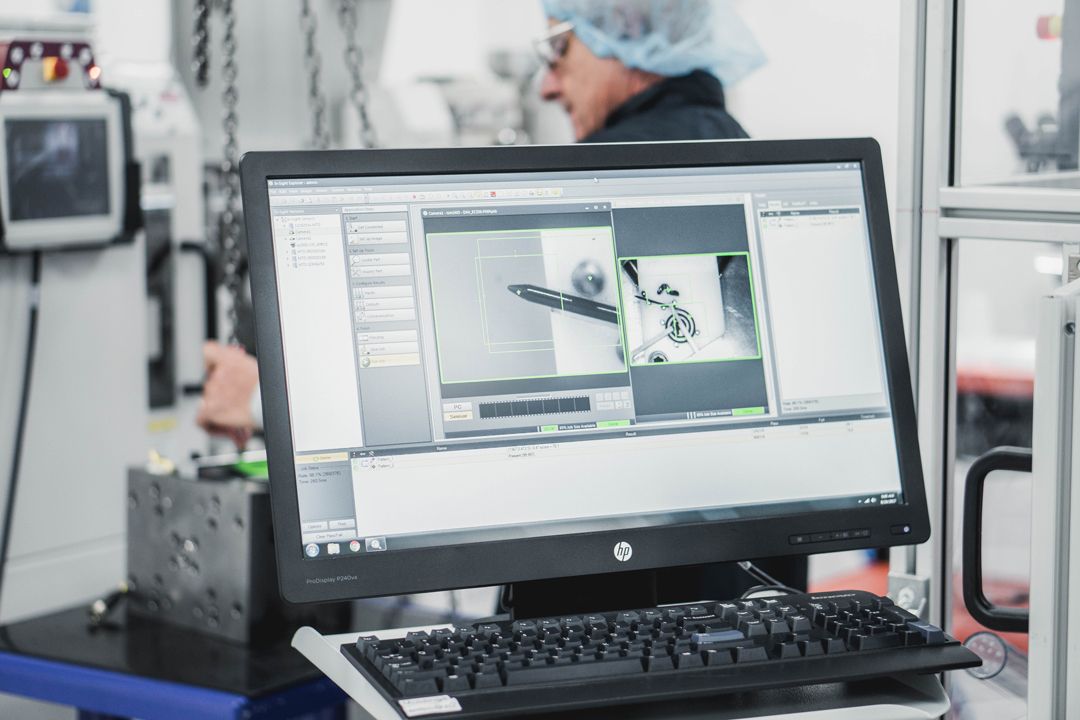

In-Line Inspection Systems

By implementing in-line inspection systems, we are able to verify the absence or presence of details down to .0001”. This allows our clients the peace of mind that every part is 100% correct.

Process Monitoring & Control Systems

Another line of defense that we employ is RJG eDart that speeds the visual inspection process up and can tighten the window on how a cavity is packed, sort from good and bad, and predict dimensions. We have developed this software for micro molding components to where it can actually predict what a dimension will be by assessing how cavity pressures impact particular dimensions.