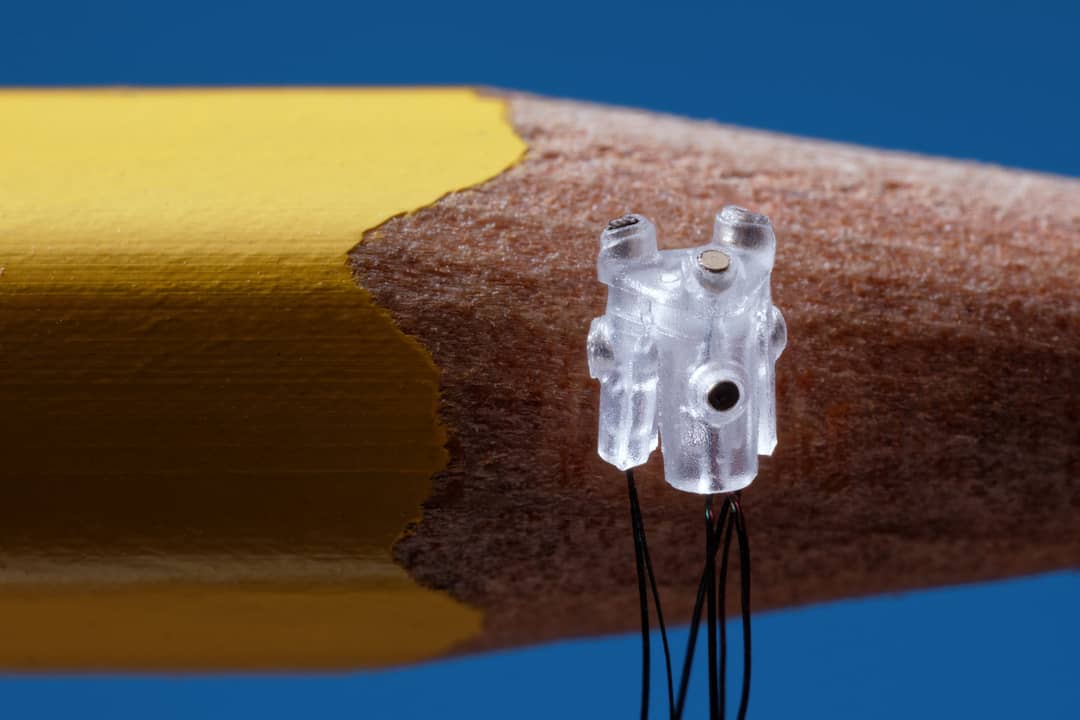

Micro Material: This micro medical device is overmolded with Polypropylene (PP).

Micro Features: The six (6) tiny electrodes with leads attached were manually hand-loaded into the tool to create this part. The diameter of each of the electrodes is 400 microns (0.4mm) and the lead diameter is 50 microns.

Description: Extremely tight tolerances were needed to maintain the exact electrode positions. This resulted in a tool that resembled a jigsaw puzzle, with electrodes being hand-loaded into three tiny pieces of steel prior to overmolding.

Are you developing an overmolded micro medical device?

Talk to MTD.

MTD specializes in overmolding—a process for molding two or more materials together to form a component. We offer insert molding and multi-shot (or multi-material) molding. Because all our services are under one roof, our engineers can efficiently resolve problems and challenges for the most complex overmolding design.

Our in-house CT scanning capabilities allow us to analyze overmolded parts with metal or different densities of plastic materials, and to accurately measure internal features.

We also excel at cost-effective, high-volume production through robotics and automation. Our custom micro medical device assembly solutions and packaging is the last step in producing your micro medical device.