Services • Micro Molding

Overmolding

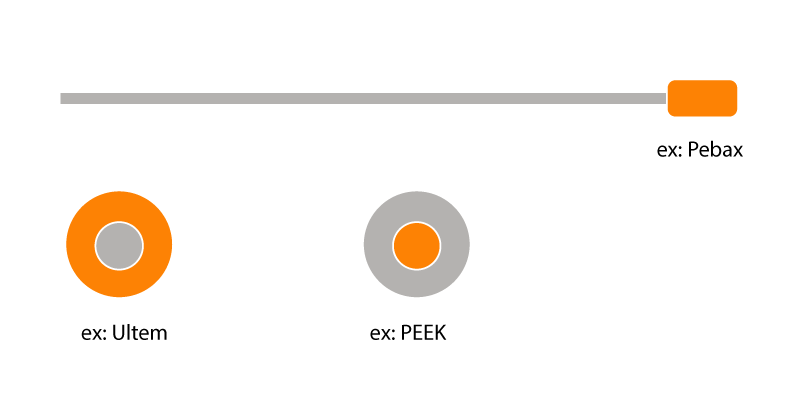

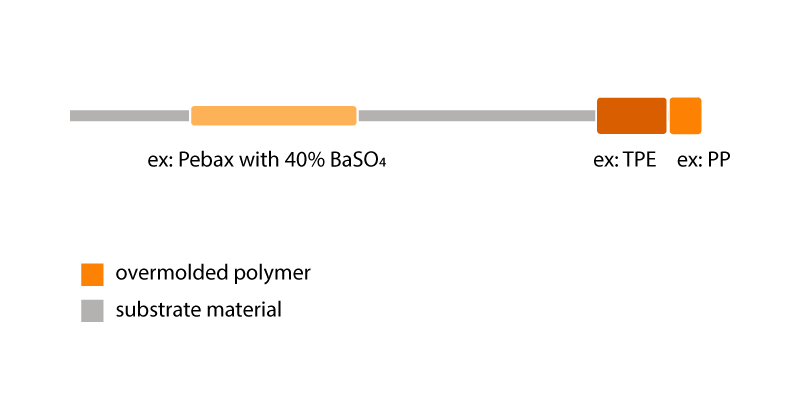

Some micro projects require specialty micro injection molding processes, such as overmolding. Overmolding involves two or more materials molded together to become one part. Examples include molding plastic over plastic or molding plastic over a preformed part, such as a metal insert or delicate electronic. (See examples of common polymers and substrates below.)

MTD specializes in two types of overmolding:

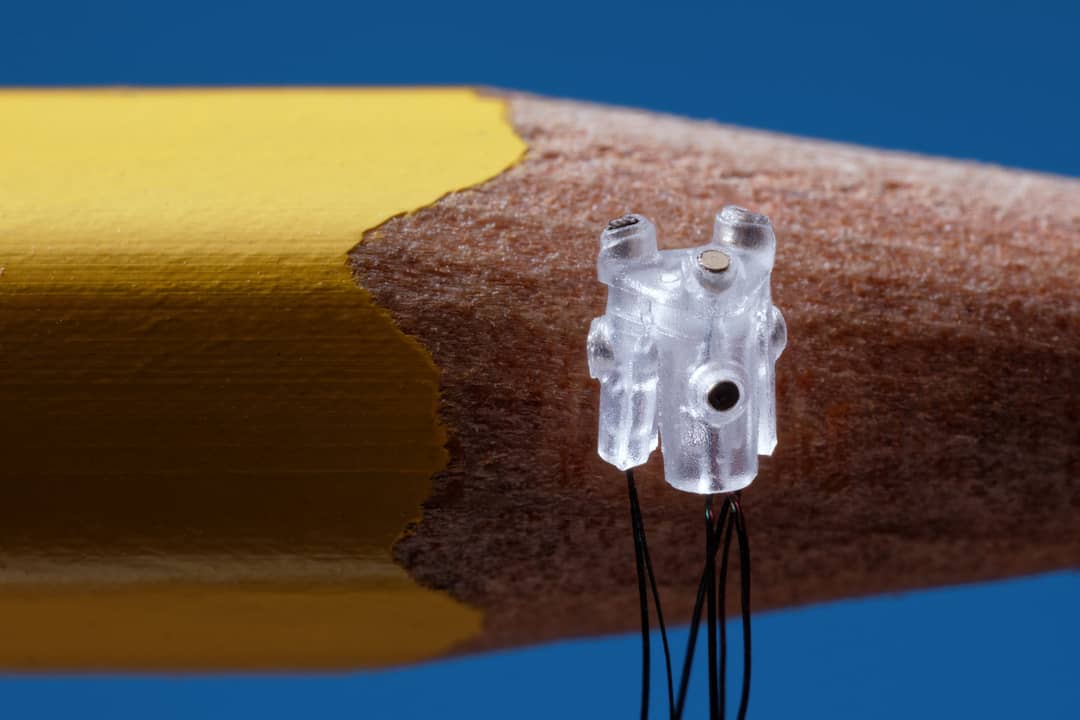

Overmolded Electrodes with Leads

Made from Polypropylene, each of the six tiny electrodes have a diameter of 400 microns (0.4mm). The lead diameter is 50 microns.

Overmolded Surgical Hypotubes

The .011″ diameter overmolded surgical hypotubes have an extremely small tube-to-tube offset.

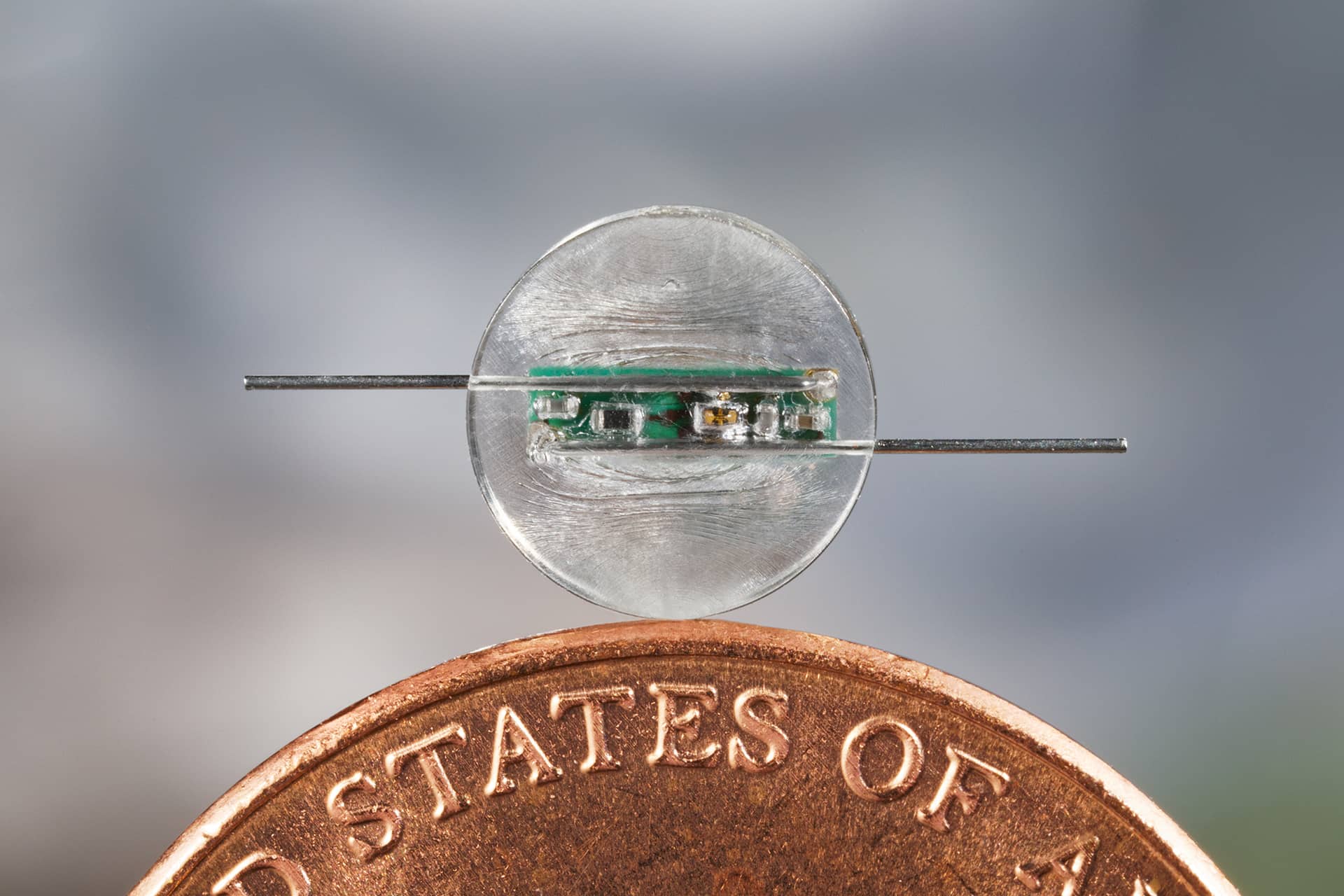

Overmolded Sensor

This miniature medical sensor was gently overmolded with a medical-grade acrylic.

Benefits of MTD’s Overmolding Process

- High part precision achieved by leading edge molding equipment, capable tooling, and robust validation procedures

- Shot-to-shot consistency guaranteed by instrumented molds

- Improved part functionality (i.e. creating a water-resistant seal)

- Cost-effective high volume production achieved through robotics and automation

- Ultra-precise positioning of overmolding tool inserts enabled by in-line camera systems

- Avoidance of foreign materials such as glues and adhesives into the final medical device

- Significant reduction or elimination of costly and cumbersome assembly operations that can lead to failure modes and high fall-out rates