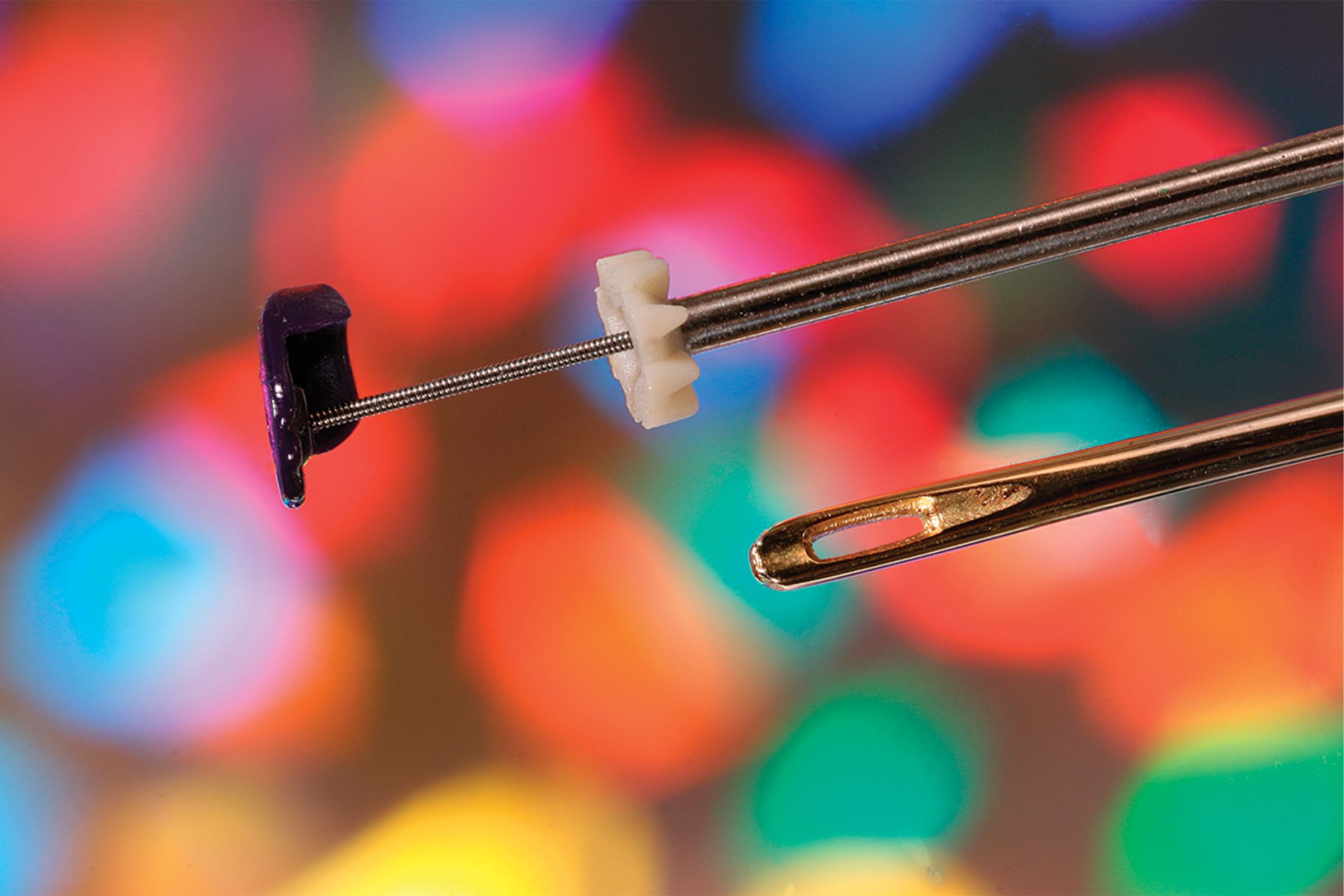

Micro Material: The device is made from Ultem, an amorphous thermoplastic polyetherimide (PEI) resin.

Micro Features: The overmolded assembly design has a spring OD of 0.11″ (0.28mm). The Ultem wall thickness is 0.012″ (0.30mm).

Description: The assembly device and mating overmolded tube were components of an endoscopic suturing device used in a non-robotic, minimally invasive surgery. The laparoscopic procedure deployed a circular pattern of staples to create a closure.

Are you developing an overmolded micro medical device?

Talk to MTD.

MTD specializes in overmolding—a process for molding two or more materials together to form a component. We offer insert molding and multi-shot (or multi-material) molding. Because all our services are under one roof, our engineers can efficiently resolve problems and challenges for the most complex overmolding design.

Our in-house CT scanning capabilities allow us to analyze overmolded parts with metal or different densities of plastic materials, and to accurately measure internal features.

We also excel at cost-effective, high-volume production through robotics and automation. Our custom micro medical device assembly solutions and packaging is the last step in producing your micro medical device.

Our experienced team will help you refine and develop your design, so you can produce a high quality medical device and get it to market quickly.