Jun 7, 2017 | Micro Insights

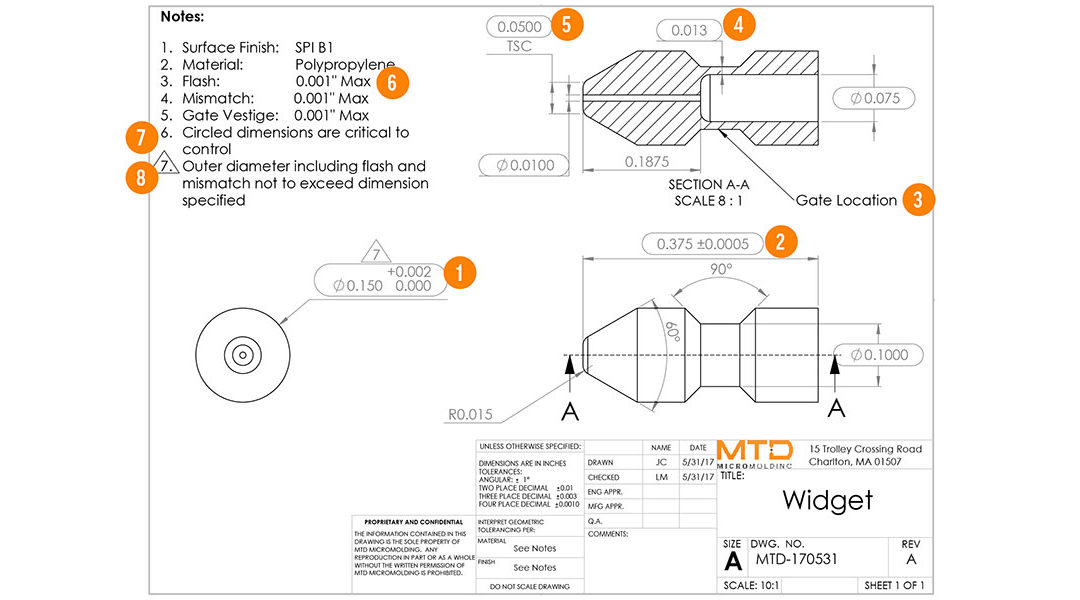

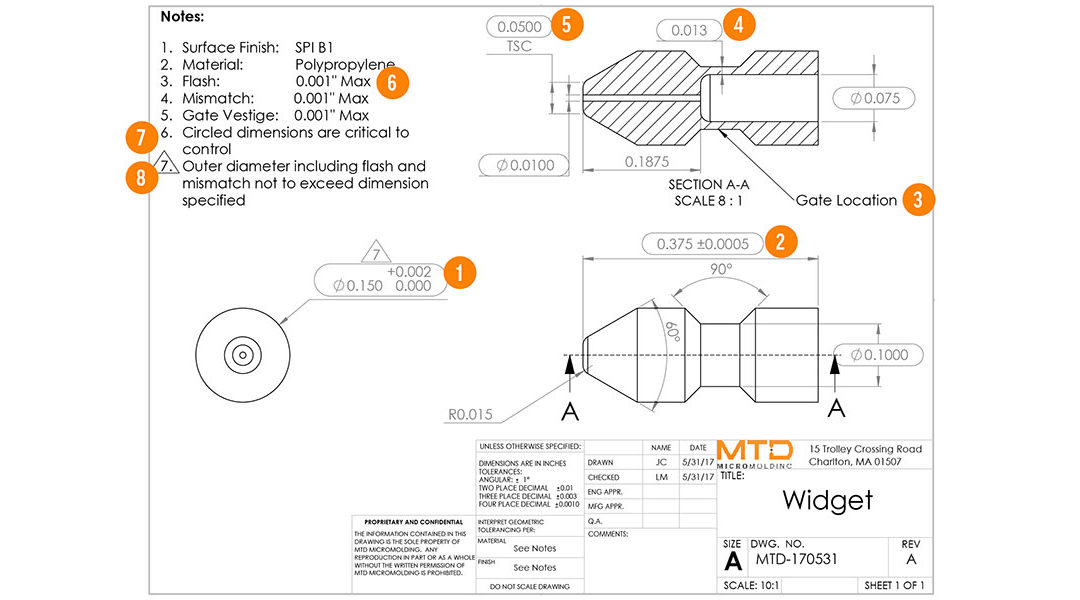

Nothing is more frustrating for micro part designers than to spend countless hours on a new drawing, only to get to the manufacturing phase and find out they need to make significant revisions or compromises.Here are some recommendations from MTD’s tooling department...

May 18, 2017 | Micro Insights

For micro medical components, there is a wide variety of materials to choose from. Most micromolding materials fall into two categories: thermoplastics and bioabsorbables. Thermoplastics are polymers that become pliable and moldable above a specific temperature and...

May 15, 2017 | In the News

On April 26, MTD accepts the Manufacturing Excellence Award for small business category at Worcester Business Journal’s 2nd Annual Manufacturing Summit. The event took place at The College of the Holy Cross in Worcester and was attended by the best of the best...

May 15, 2017 | In the News

In this month’s edition of Plastics Engineering magazine, there was a unique focus on micro injection molding – a growing trend in the industry. Why is it trending? Simple: devices are continuing to get smaller and smaller. And advanced injection molding...

May 15, 2017 | In the News

The art and science of micro-moldmaking Cutting Tools Engineering magazine ran a special issue this month with a focus on micro. Topics included making molds with submicron features, laser machining micro medical parts, and tools with hair-thin diameters. MTD was...