Jun 4, 2020 | Micro Insights

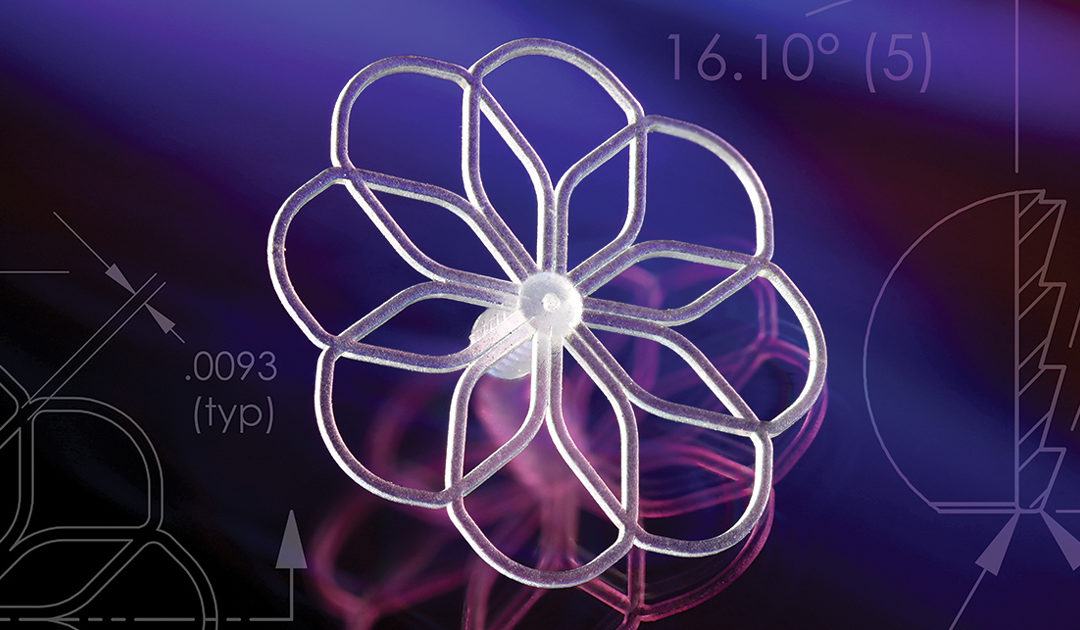

One of the most common questions that our team hears from medical OEMs seems simple: how thin can we go? But the answer is: it depends. One of the main factors is material choice. Can your design use a thermoplastic material that’s better suited for ultra-thin...

Feb 28, 2020 | Micro Insights

When Plastics News interviewed our president, Dennis Tully, last year for Plastics News Processor of the Year, he shared how MTD Micro Molding approaches problem-solving. We include teamwork in everything we think about… Are we always going to make the right decision?...

Jun 28, 2018 | Micro Insights

Everyone wants to be innovative, to find the next big idea in their field. Innovation doesn’t strike like a lightning bolt out of the blue. It takes collaboration and a deliberate search process. In Stand Out, a book about finding your breakthrough idea and becoming...

Apr 25, 2018 | Micro Insights

It is easy to say “do it right the first time,” but when it comes to selecting a micro-manufacturer, it can be difficult for medical OEMs to navigate the choppy waters of finding a capable molder for their designs while also carefully considering the...

Feb 28, 2018 | Micro Insights

In a rapidly growing and evolving industry like medtech, how do you find the next breakthrough idea? In her book Stand Out, Dorie Clark recommends asking yourself the following questions: What are others overlooking? What are the assumptions underlying your field?...

Aug 2, 2017 | Micro Insights

The July issue of Medical Design & Outsourcing focused on contract manufacturing and addressed the trend of OEM and contract manufacturer consolidation. With all the of the mergers and acquisitions taking place in the medical manufacturing space, you can’t...