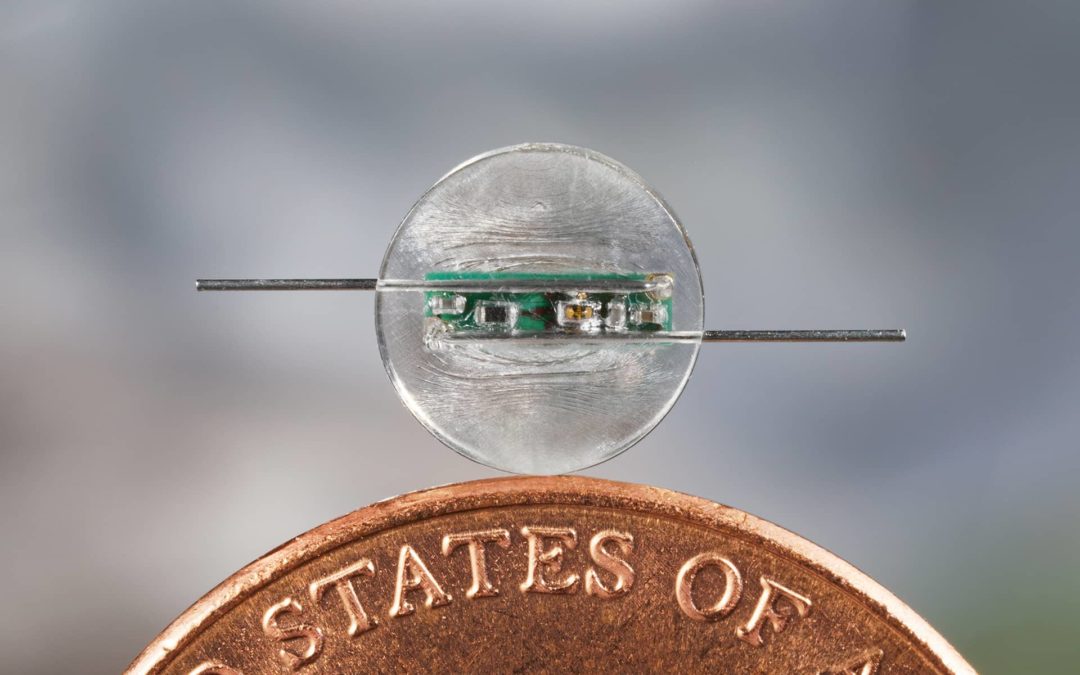

In this Medical Product Outsourcing (MPO) article, MTD Micro Molding discusses how the micromolding industry is achieving even greater levels for the smallest parts while still maintaining important properties. Micro molding continues to be in high demand in the medical device industry and molders are using all their skills and the newest equipment to reliably create incredibly small, complex features, even from sensitive materials.

Discussing practical and theoretical limits of part size for micromolding:

“This limit can change drastically given the complexity of the part geometry, application of the device, and the type of polymer material. Different materials respond differently to factors such as pressure loss, compressibility, and even thermal conductivity, which can influence how quickly a flow front cools and how drastically the viscosity increases as flow continues.”

Kyle Kolb, Tooling Supervisor