Historically, 20% of new projects at MTD each year have been “rescues” – failed attempts by others. MTD’s success rate? 100%.

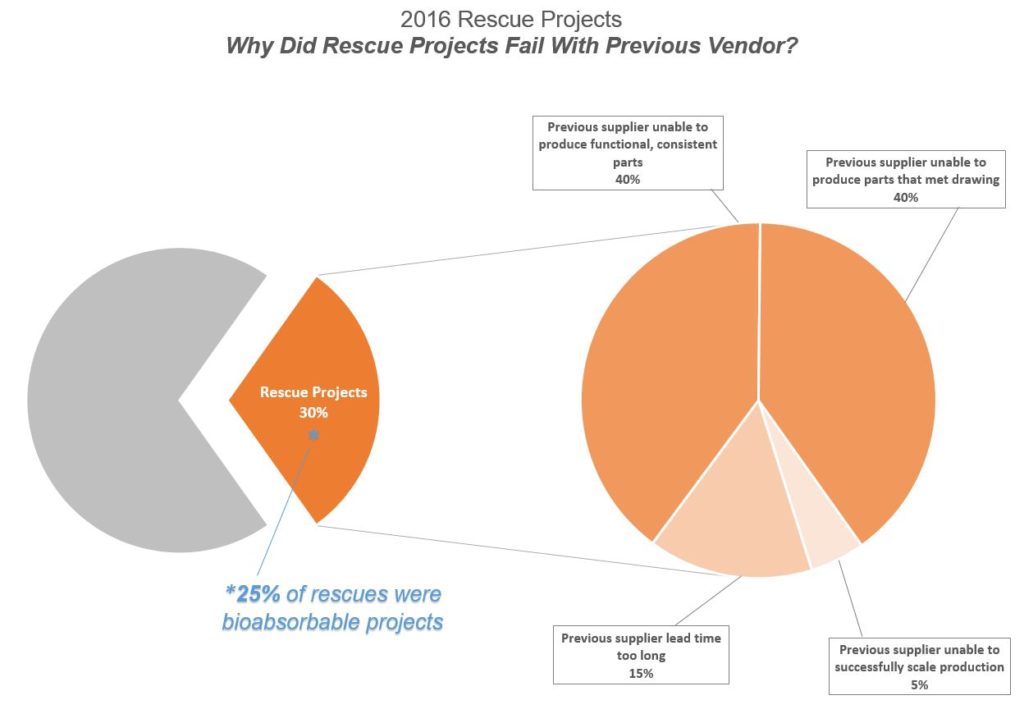

In 2016, the annual customer survey results indicated that this rescue percentage increased to 30%, with about 25% of those projects being bioabsorbable.

Why did these projects fail at the previous supplier? The majority of respondents replied that they left their previous molding vendor due to issues with (1) inability to produce functional, consistent parts and (2) inability to produce parts that met the drawing.

40% Previous supplier unable to produce parts that met drawing

40% Previous supplier unable to produce functional, consistent parts

15% Previous supplier lead time too long

5% Previous supplier unable to successfully scale production

Failing at a molding supplier wastes valuable time and money when racing to get a medical device to market. How can this be avoided? Select a micro molder that can prove they have the knowledge and experience to successfully produce your product.

- Don’t always go with the lowest bidder.

- Make sure a molder has the right equipment to produce your component consistently, to print.

- Make sure a molder has worked with parts of similar geometry and can show you samples of those projects.

- Most important, make sure they demonstrate an ability to effectively work with your desired material. Knowledge counts, especially when it comes to unique materials.

Why is your product failing at your current supplier?

Read MTD’s rescue stories here or contact us today to rescue your design.