CHARLTON, MA – (6/7/2021) – MTD Micro Molding celebrated the grand opening of its expanded medical micro injection molding facility with a ribbon-cutting ceremony on May 27. Guests included industry partners and community leaders, who had the opportunity to tour the new space in person.

While the exterior of the expansion was completed last fall—effectively doubling the manufacturing space—the interior space required a few more months to finalize details, move equipment, and get new cutting-edge machinery in place.

John Clark, MTD’s tooling & molding specialist who oversaw the completion of the expansion project, explained, “When laying out the new space, we did it strategically to ensure project flow and tracking, improving timing and efficiency.” As a single-source manufacturer for ultra-precise micro medical components, this is critical for helping customers achieve faster speed to market—regardless of how challenging the design, novel the polymer material, or breakthrough the concept.

MTD has placed on Plastics News’ Best Places to Work list for four consecutive years. Touring the expansion, it’s easy to see why. As tooling supervisor Kyle Kolb said, “The added space allows for more personal space for employees, allowing them to better concentrate. The extra space has allowed better organization and storage.” The expansion even includes an impressive gym, so employees can better maintain their well-being.

MTD continues to grow at a rapid pace. It’s actively hiring new employees, purchasing more state-of-the-art equipment, and responding to customer’s evolving needs, such as the increased demand for custom packaging and assembly services for micro medical components.

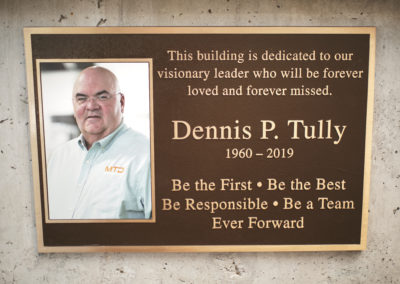

As part of the ceremony, MTD executive vice president Gary Hulecki unveiled a cornerstone plaque honoring Dennis Tully, MTD’s late president and visionary leader who masterminded the expansion before his unexpected passing in 2019. As Hulecki shared, “[Dennis] would never tell you what to do or how to do something, but you could always count on him to help you frame the problem and think through the issues you needed to consider before proceeding.”

Charlton town administrator Andrew M. Golas recalled, “When I started as Town Administrator, MTD was the first company in town to invite me in to see their facility and welcome me to Charlton.” Perhaps that’s not surprising from a business that has “Be the First” and “Be Responsible” as two of its five core values.

At the ceremony, MTD owner Darlene Tully had a long list of people to thank for helping Dennis’s vision become reality, from local and state officials to its contractors and partners to the MTD team. As Clark aptly said, “it allowed us to reach this major milestone for the company and for Dennis’s legacy.”

About MTD Micro Molding

Founded in 1972, MTD Micro Molding custom-crafts ultra-precision molded components that meet the exact requirements of companies in the medical device industry. In-house tooling, unparalleled bioabsorbable molding expertise, ISO 13485 certified systems, state of the art equipment – all under one roof. Our exclusive focus on bioabsorbable and drug delivery medical micro molding ensures successful delivery of complex custom products that nobody else can produce.

To learn more, visit mtdmicromolding.com or come tour our facility in Charlton, Mass.

# # #