News and Insights

Get the latest insights, innovations, and news about medical micro molding and our MTD team.

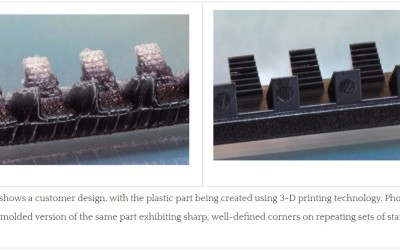

Experimenting with Micromolding and 3-D Printing

It is natural that the successes experienced by those using the method in the “Macro-world” would inspire similar experimentation in the “Micro-world”, too.

A Singular Focus on Medical Micro Molding

Members of MTD Micro Molding’s team recently participated in an email interview with D2P to discuss some of the factors that make the company unique.

Insider Q&A: Dennis Tully | Pt. 1

We sat with Dennis as part of our Insider Q&A series and asked him a series of questions to get his perspective on common questions that we field from folks in the medical device industry.

11 Tips to Keep Your Molding Project from Failing

Selecting a manufacturer to build your tool, validate the molding process, and be your partner through full-scale production is an important decision for the success of your program.

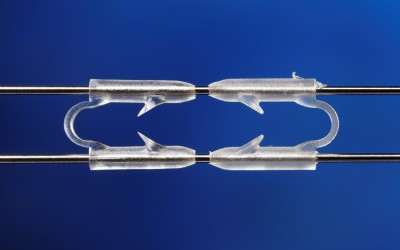

MTD is Top 10 Finalist for Innovation Award

Boston BIOMEDevice is approaching and our friends at Qmed have selected the semifinalists for the BIOMEDevice Boston Innovation Prize.

MTD Attends Executive Forum as POY Finalist

MTD had an incredible night in Naples, FL at the Plastics News’ Executive Forum. What an honor to be included in the finalist line up and it was great to meet all the folks that represented these amazing companies. We certainly hope to be back next year as a finalist, and hopefully, a Processor of the Year winner!