Feb 1, 2017 | Micro Insights

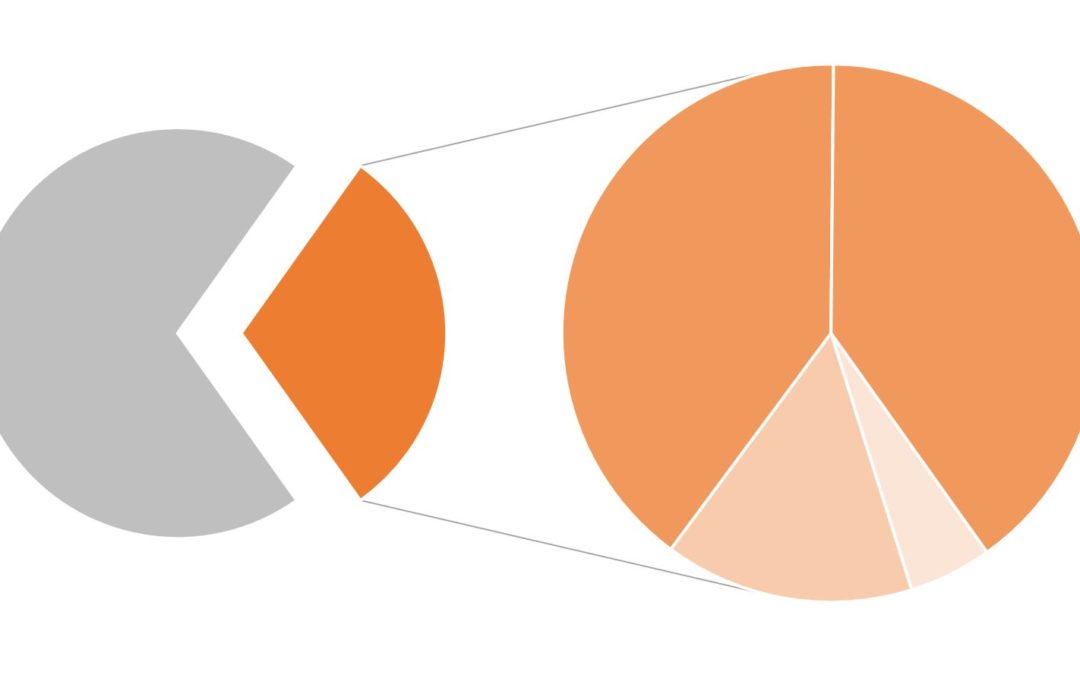

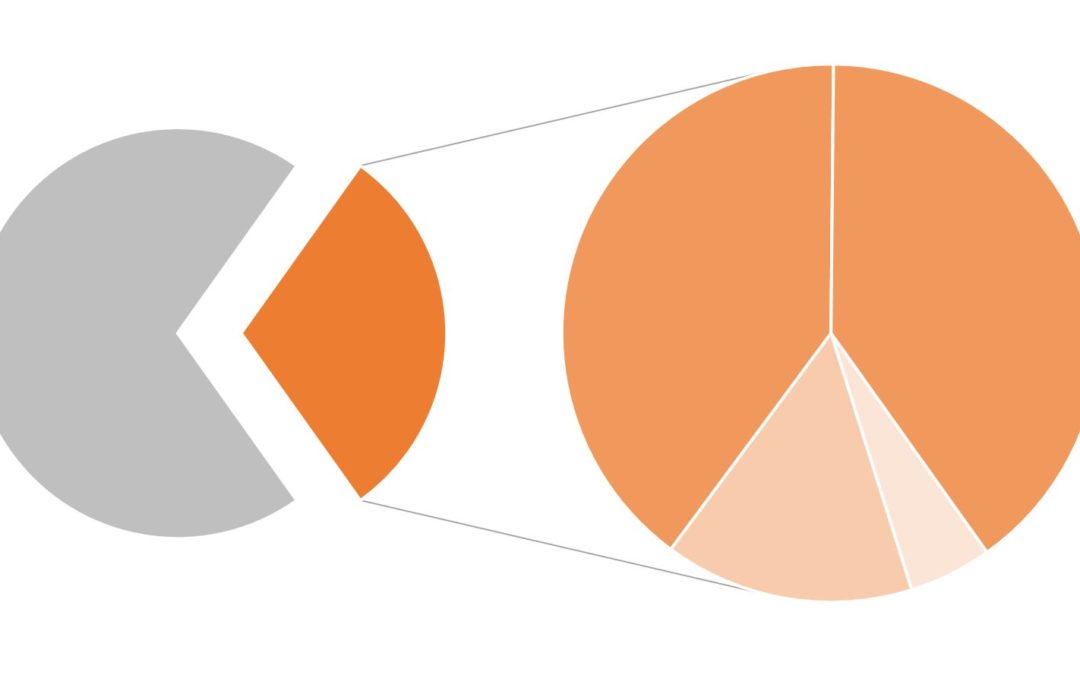

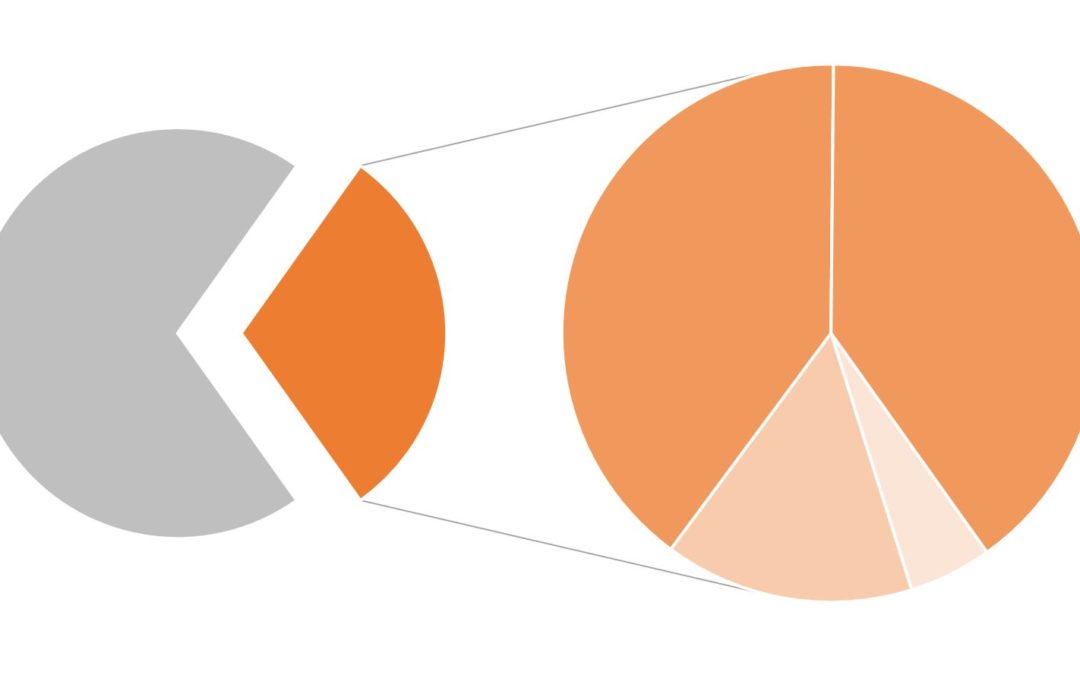

Historically, 20% of new projects at MTD each year have been “rescues” – failed attempts by others. MTD’s success rate? 100%. In 2016, the annual customer survey results indicated that this rescue percentage increased to 30%, with about 25% of...

Nov 14, 2016 | Micro Insights

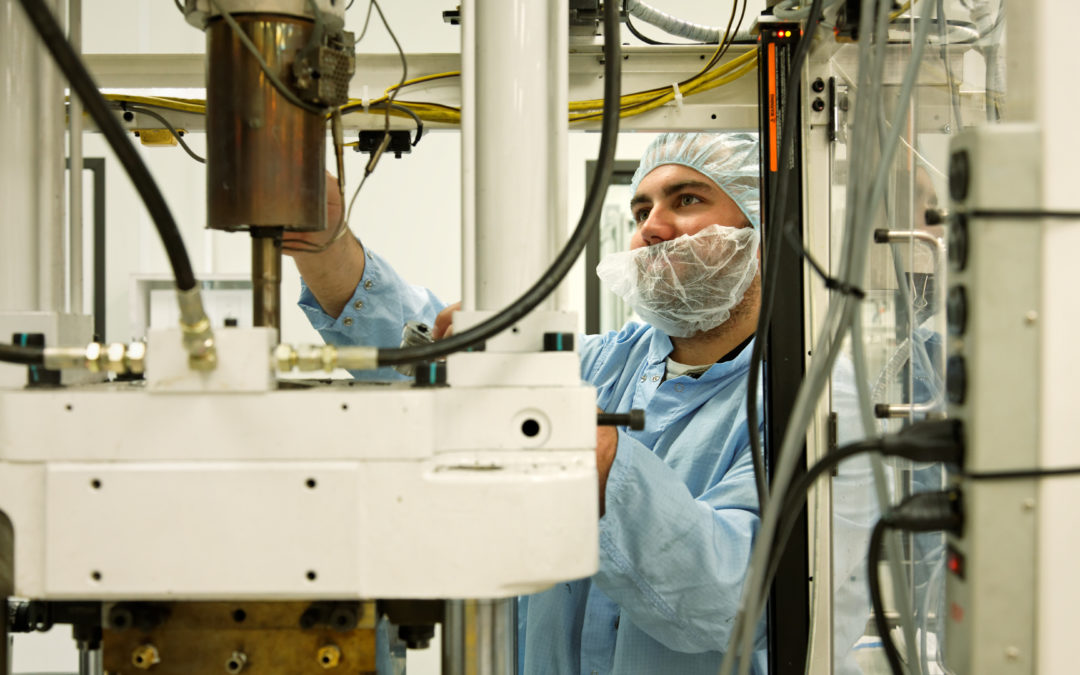

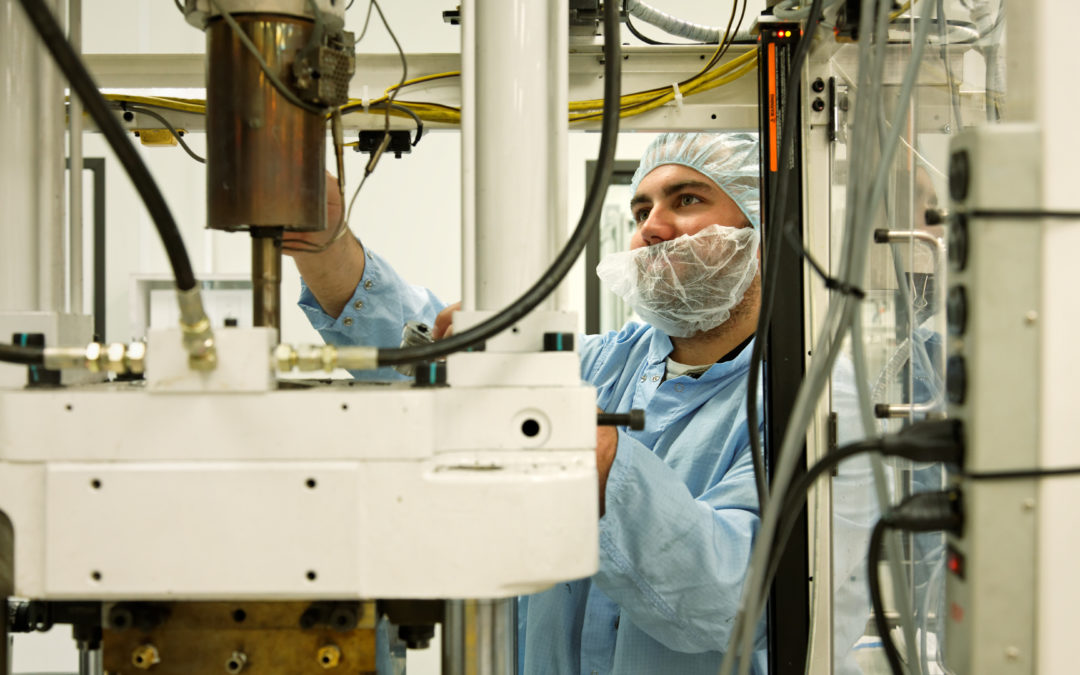

With the steady increased adoption of bioabsorbable polymers and sensitive materials for micro medical device components, temperature controlled environments for manufacturing and storing these critical pieces has become essential. Due to the sensitivity of...

Nov 3, 2016 | Micro Insights

How is medical micromolding different? Medical micro injection molding requires much more specialized equipment than traditional micro injection molding. In conventional micro injection molding machines, the screw performs four basic actions: melt, feed, convey and...

Sep 30, 2016 | Micro Insights

The smallest parts often carry the greatest importance relative to the functionality and safety of a medical device. MTD Micro Molding refers to its micro molding tools – its road map to success, if you will – as the company’s “6 Sciences.” Embracing this approach can...

Aug 25, 2016 | Micro Insights

When a large medical equipment manufacturer was searching for a micro molding alternative to an inefficient process, the word “no” came up in every vendor conversation. That is, until they found their “yes” provided by one supplier. Being told “no” so often had almost...

Jun 2, 2016 | Micro Insights

1. Find Solutions: The MD&M East expo floor is your central hub to share ideas, challenges, and solutions with almost 10,000 medtech professionals and 1,000 exhibitors. Don’t miss your chance to meet top-notch medical suppliers, showcasing innovative products a...