Feb 28, 2018 | Micro Insights

In a rapidly growing and evolving industry like medtech, how do you find the next breakthrough idea? In her book Stand Out, Dorie Clark recommends asking yourself the following questions: What are others overlooking? What are the assumptions underlying your field?...

Aug 2, 2017 | Micro Insights

The July issue of Medical Design & Outsourcing focused on contract manufacturing and addressed the trend of OEM and contract manufacturer consolidation. With all the of the mergers and acquisitions taking place in the medical manufacturing space, you can’t...

Jul 6, 2017 | Micro Insights

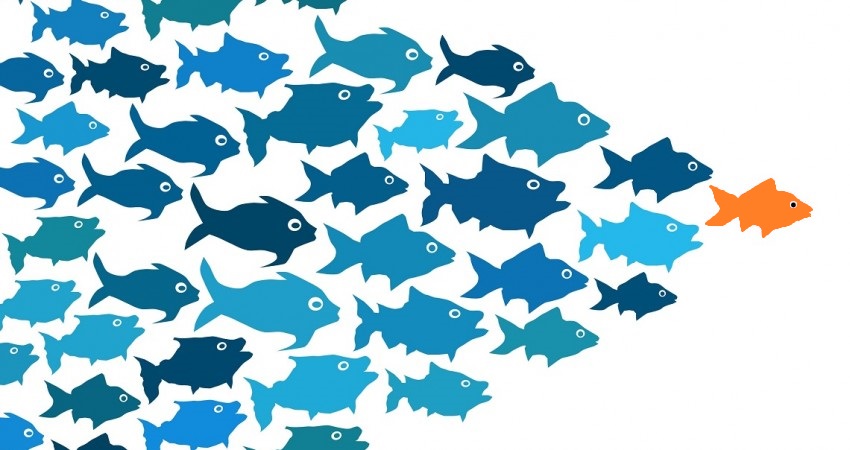

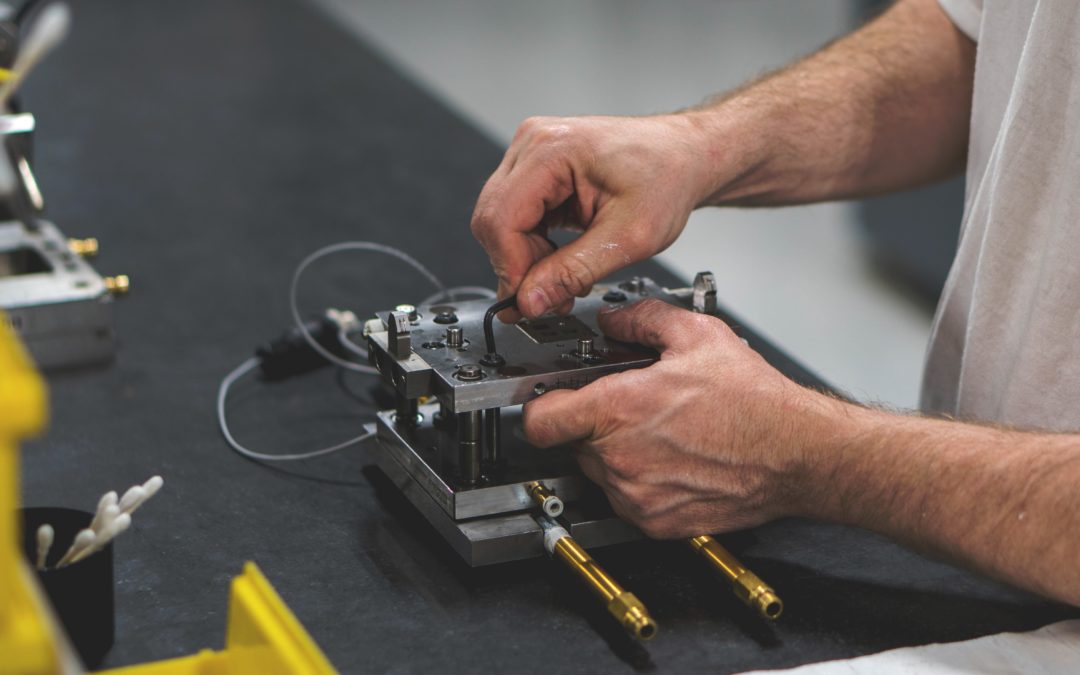

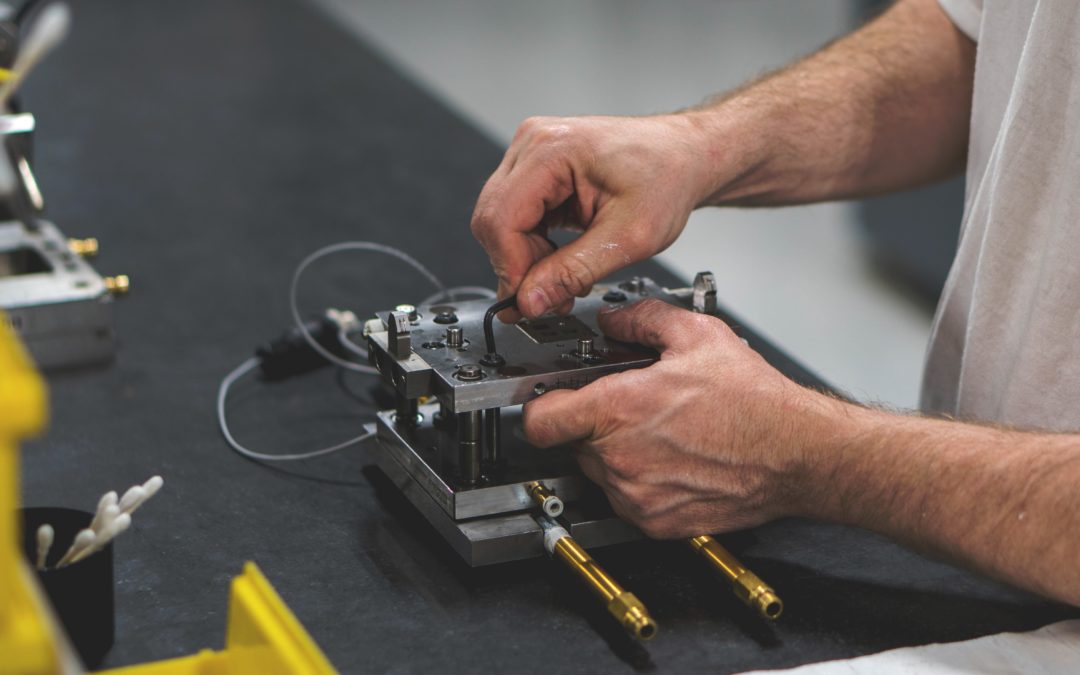

How are the main processes and strategies different for micro molds vs. macro molds? 1. Design Smaller runners, smaller gates, and because of the tiny details in the designs, most of the ejector pins are very small (sometimes as small as 0.010 inch). There also are...

Jun 7, 2017 | Micro Insights

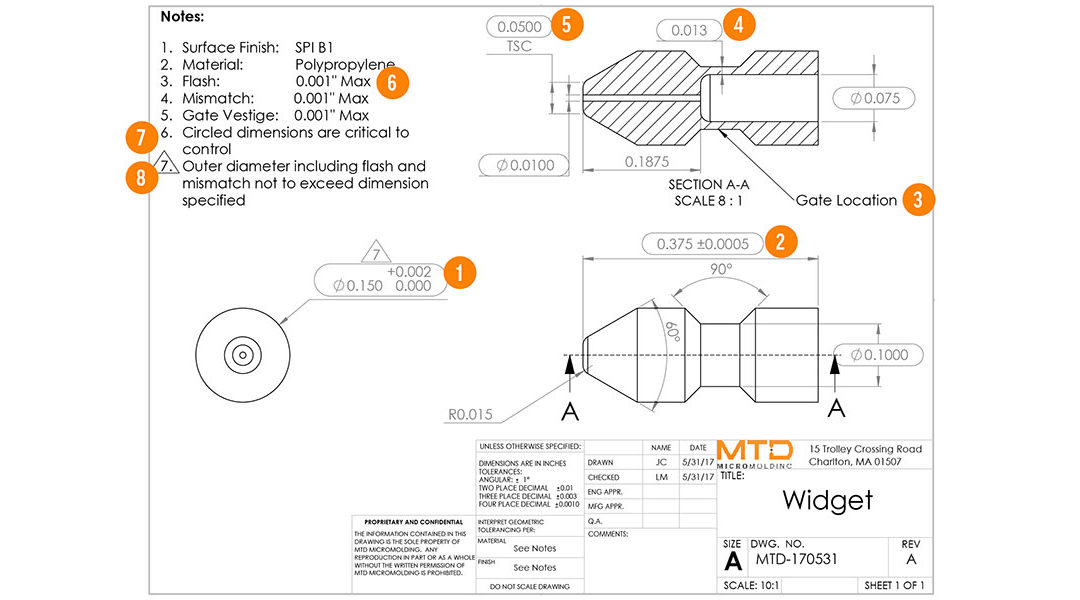

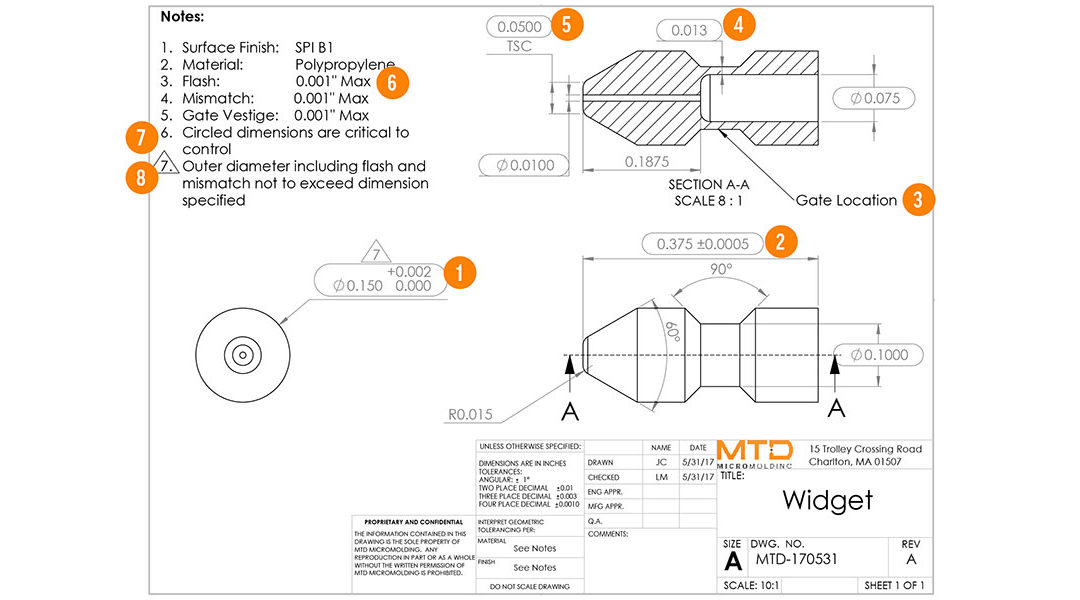

Nothing is more frustrating for micro part designers than to spend countless hours on a new drawing, only to get to the manufacturing phase and find out they need to make significant revisions or compromises.Here are some recommendations from MTD’s tooling department...

May 18, 2017 | Micro Insights

For micro medical components, there is a wide variety of materials to choose from. Most micromolding materials fall into two categories: thermoplastics and bioabsorbables. Thermoplastics are polymers that become pliable and moldable above a specific temperature and...

Apr 17, 2017 | Micro Insights

Datum Feature Symbol Placement Our engineering teams have reviewed hundreds of Micro Part Designs over the years. And one mistake that is commonly seen in micro part drawings is the placement of the datum feature symbol. When in line with a dimension line, like datum...