Thermoplastics Portfolio

These micro medical components are made with thermoplastics, which is a medical grade polymer that becomes pliable above a specific temperature, but returns to its rigid state upon cooling. See our Thermoplastic Materials page to learn about the types of materials we work with.

Our specialized micromolding process and capabilities allows us to achieve >95% part’s model geometry produced without exception, even with extremely small and precise features like ultra thin walls.

PEEK Implant

Micro Materials: This device is molded from PEEK (PolyEther Ether Keytone). Micro Features: 0.022″ (0.56 mm) ID Passage for the implant. Description: This PEEK implant is used as a soft tissue-bone anchor device in orthopedic or minimally invasive reconstructive...

Strain Relief Device

Micro Material: This ablation tip is molded Glass Filled LCP (Liquid Crystal Polymer). Micro Features: The device design features 0.030″ (0.76 mm) ID and 0.950″ (24.13 mm) OAL. Description: The strain relief device has extremely long flow length; minimum...

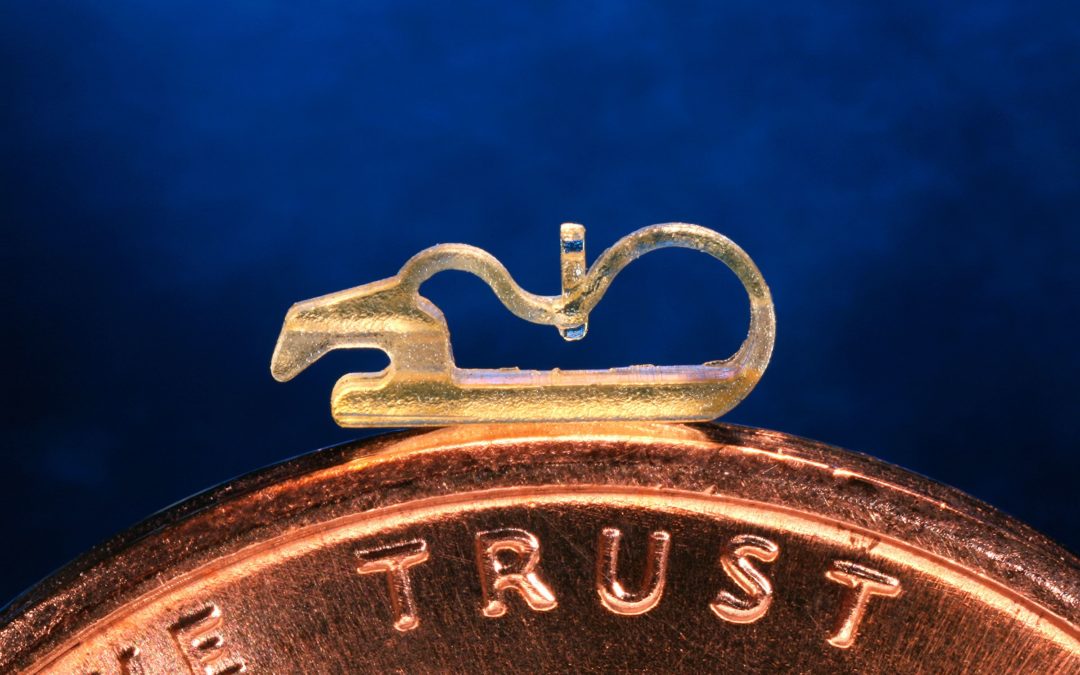

Vascular Connector

Micro Material: The device is molded of confidential thermoplastic material. Micro Features: There isn’t a straight line on this connector. Average wall thickness of 0.008″ (0.20 mm). Description: The vascular connectors are surgical implants that form...

Micro Nozzle Component

Micro Material: The device is molded of Polypropylene (PP), a thermoplastic material. Micro Features: The micro nozzle component key feature is a 60 micron diameter (0.0024″), thin walled, exit hole with micron tolerances Description: Micromolded Pipette Tip...