Micro Molding Innovation Since 1972

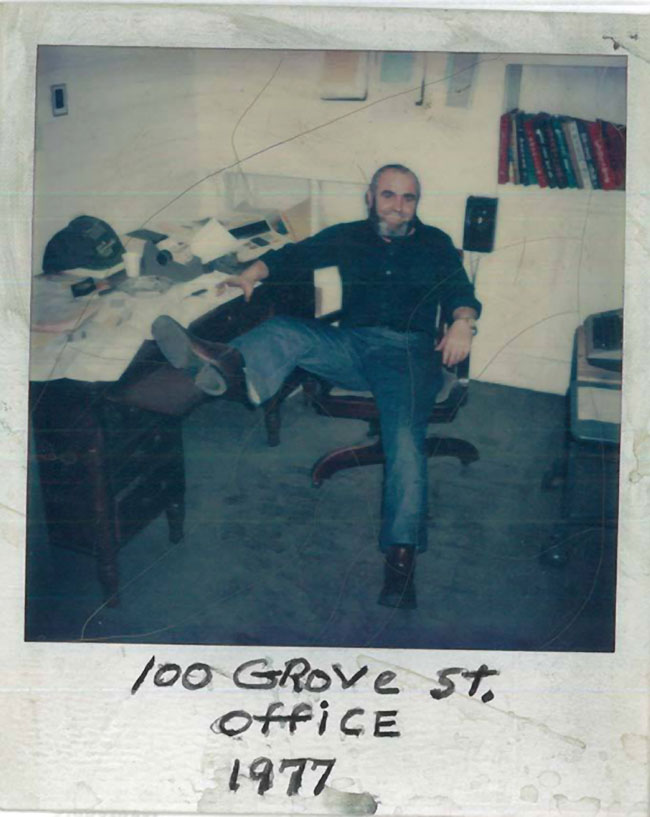

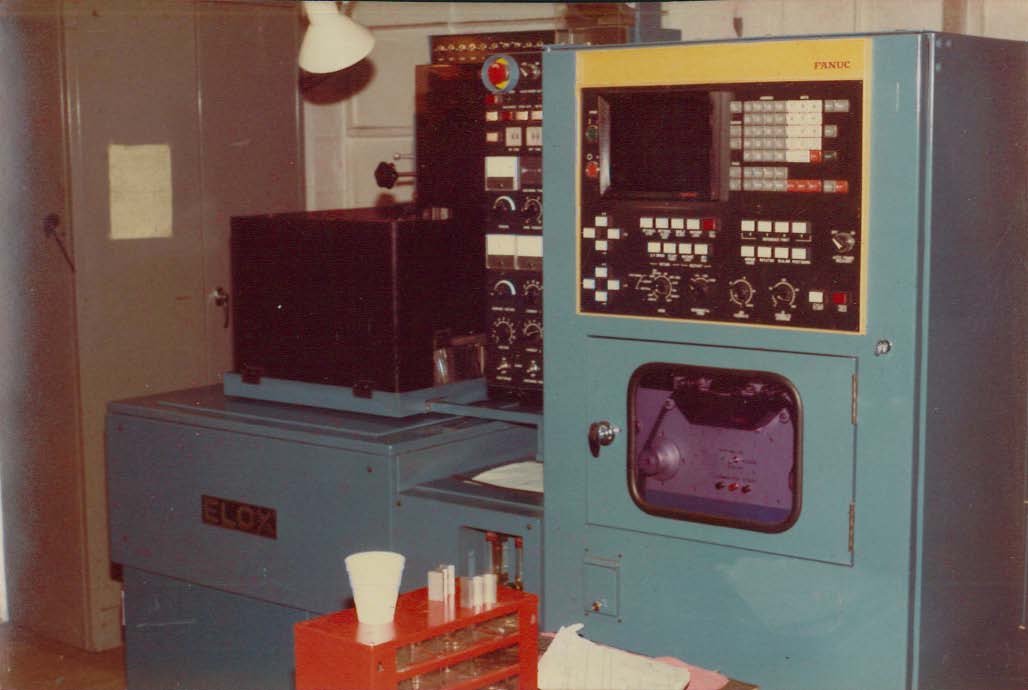

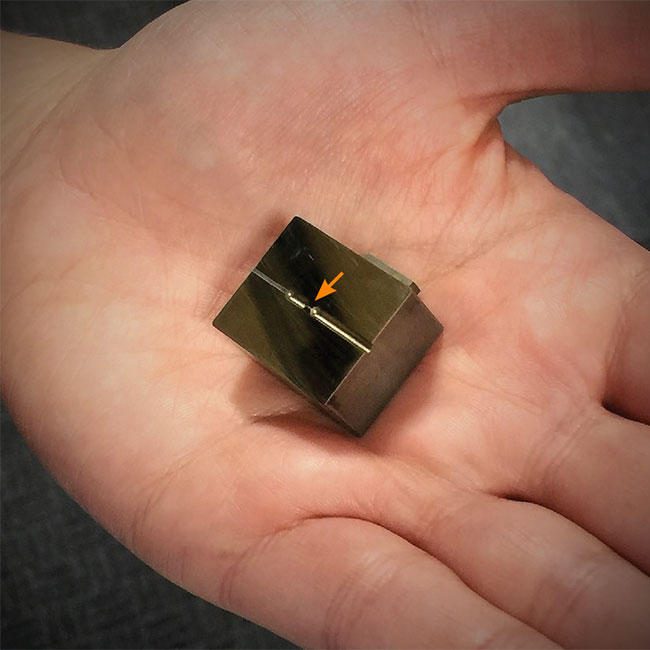

Miniature Tool & Die began its operations in the basement of founder Richard J. Tully’s 200-year-old Colonial home in Charlton, Massachusetts. The main product at that time was making connector molds for the Electronics Industry. In January of 1975, Miniature Tool & Die, Inc. bought an existing machine shop, Layson Machine, which was located at 100 Grove Street in Worcester, Massachusetts. Layson Machine had an EDM (Electrical Discharge Machine) that was the determining factor for the acquisition. This EDM machine was one of the very few in this area at the time. EDM was in its infancy but the potential was bright. This type of machining was not an easy sell and business was not too brisk in the mid ’70s. In June of 1977, Miniature Tool & Die, Inc. bought a new EDM machine and, at the same time, moved to 127 Cambridge Street in Worcester, Massachusetts. Business was picking up and EDM was now a force in the machining industry. We continued to build Connector molds for the Electronics Industry along with doing EDM work for mold shops in the area. In 1982, Miniature Tool & Die bought a CNC Wire EDM Machine to expand the EDM capability further. This was one of the first machines of its kind in New England. That machine allowed MTD to create details that were otherwise not possible. In 1985, we purchased our second Wire EDM machine and have continued to expand in the CNC area with the purchase of the Elox CNC vertical EDM, the CNC Okuma Milling machine, an Okuma CNC Turning Center, and our newly acquired Herbert Walter 24 position Automated Tool Changer CNC EDM machine In 1998, Miniature Tool & Die, Inc. moved into our brand new employee designed 16,500 square foot facility on 15 Trolley Crossing in Charlton, Massachusetts. This was considered an investment in our future. This same year, we began working on a new niche: micro-mold building. Very little was known about micro mold building or micro molding in 1998, but we expected the future to be bright. Our previous mold making business allowed MTD to establish relationships with a few major medical OEMs. With the encouragement of those customers, we began micro molding in 2001. MTD’s first “micro” molding machine was a Nissei Denkey. This is the year of the first bioabsorbable molding project at MTD as well. 1 Sodick vertical press and 1 Sodick horizontal press purchased. Purchased first RJG eDart system ever used for a micromolding application. Micro injection molding accounted for 25% of MTD’s revenue. MTD stopped producing micro tools for other companies. MTD was awarded the NIH grant for an SBIR program: studying micro flow of plastics. To study effective flow, had to add testing equipment – which became some of the building block tools of what we utilize today for micromolding projects. This was a 2-year process, ending in 2008. During 2006, high volume bioabsorbable micromolding also began at MTD. MTD’s micro molding revenue surpassed the machining revenue for the first time. In 2008, the founder of MTD, Richard Tully, retired. With Dick’s retirement, the organization was passed onto the second generation led by Dick’s son, Dennis Tully. MTD remains committed to Dick’s original philosophy to find and commit to a niche as well as to respond quickly, precisely, and efficiently to our customer needs. Between 2008–2009, MTD upgraded all critical equipment in the in-house tooling department. We added Sarix micro EDM milling technology—the only system in North America at the time. On April 1, 2010, we began using our new name: MTD Micro Molding. The expectation with the new name was to help people recognize that our new business is micro molding, while our foundation is very much MTD. And so began the mission of educating medical OEMs that smaller, better critical components are possible. The focus was on providing highly specialized products that meet the exact requirements of companies in the medical, electronics, and microfluidics fields. In 2010, we also started working with international medical device companies. We stopped manufacturing turn-key molding cells for other companies, while keeping all tooling and micromolding operations under one roof at MTD’s facility. Smallest part in the world created by MTD. The ophthalmic implant for glaucoma treatment weighs in at 0.00000313 grams, with a gate measuring .0018 x .0008 inches. This year, drug-filled bioabsorbable material molding began. Pharma loss through extrusion was significantly higher than micro injection molding—practically no post-mold drug loss with MTD’s method. MTD Micro Molding ranked #1274 in the Inc. 500|5000 list due to a 3-year growth percentage of 228%. Cleanroom expansion: 1200 sq ft ISO Class 8 cleanroom to increase capacity for 8 more molding cells. First MTD process technician to become a certified Master Molder. Finalist for Plastics News’ Processor of the Year Award. First MTD molding technician obtained Plastics Technology & Engineering Certificate from the American Injection Molding Institute. MTD is the first micro injection molding company in the world to receive the MedAccred Certification. We also received ISO 13485 Certification. During this record sales year, we expanded the molding and tooling departments to best support our unique specialty in providing solutions for bioabsorbable and drug delivery components. MTD is the recipient of the 2017 Manufacturing Excellence Award based on its sharp focus on medical micromolding, intimate knowledge of its client’s needs, state of the art equipment, and continuous year-over-year revenue growth. This year, MTD also proudly celebrates their 45-year anniversary. MTD Micro Molding made the Inc. 500|5000 list for the second time due to a 3-year growth percentage of 48%. MTD obtained FDA registration at the start of 2018. This registration allows for additional services to take place at our facility for our customers including custom assembly, packaging, and labeling operations. MTD was included in the Best Places to Work list for 2018. MTD Micro Molding was also honored as a Processor of the Year finalist for 2017 and the recipient of the Employee Excellence Award by Plastics News. The company also made significant investments in innovation this year, with purchases like a Gas Chromatography System and North America’s first Mitsubishi MX600 oil wire EDM machine. MTD was named the Plastics News Processor of the Year, the plastics industry’s most prestigious award, becoming the smallest company to win the title in its 22 years. The company was also named one of the Best Places to Work in the plastics industry for the second year in a row. The awards were bittersweet due to the loss of MTD’s president, Dennis Tully, on February 28—just one week before the awards ceremony. In the spring of 2020, Dennis Tully was posthumously inducted into the Plastics Hall of Fame and his design for MTD’s building expansion was brought to life with a 12,000 sq. foot addition completed in September. In March, it was announced that MTD Micro Molding made the list of Best Places to Work for the fourth consecutive year. In May, MTD celebrated the grand opening of the expanded facility with a ribbon cutting ceremony. in 2022, MTD celebrates 50 years of miniaturization. In March, it was announced that MTD Micro Molding made the list of Best Places to Work for the fifth consecutive year. MTD Micro Molding topped the processor list of Plastics News 2023 Best Places to Work. This is the sixth consecutive year of being on the list, but the first time ranked #1.

Miniature Tool & Die Founded

Acquired Layson Machine

New EDM, New Location

First Wire EDM Machine in New England

4 CNC Machines and Second Wire EDM Machine

New Home, New Niche

Micro and Bioabsorbable Molding Begins

Purchased First RJG eDart System Used for Micro Molding

Micro Injection Molding Grows

NIH Grant for Studying Micro Flow

Micro Molding Surpasses Machining

Upgraded In-House Tooling Department

New Name for New Focus

Smallest Part in the World

Cleanroom Expansion

Processor of the Year Finalist

First Micro Injection Molder to Receive MedAccred Certification

Manufacturing Excellence Award

FDA Registration & Best Places to Work

Processor of the Year

Plastics Hall of Fame Induction & Facility Expansion

Best Places to Work & Ribbon Cutting

50th Anniversary

Best Place to Work in Plastics