Need a specialized micro molder for your medical device?

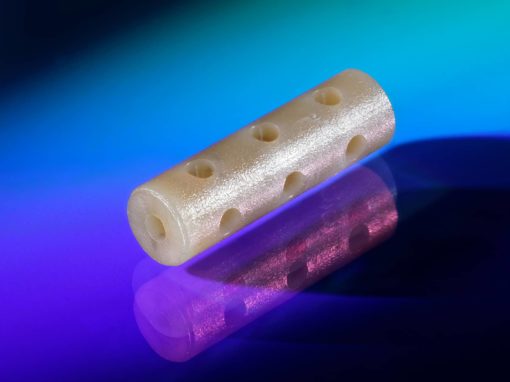

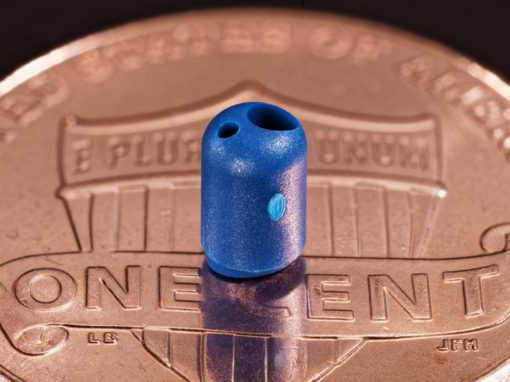

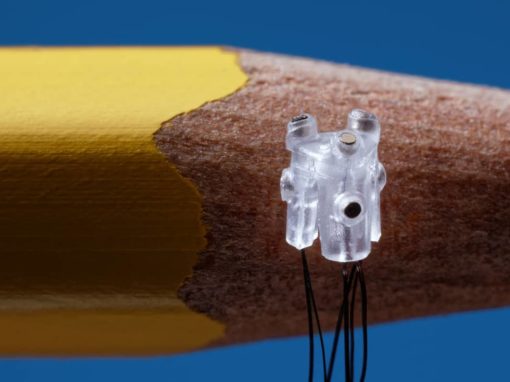

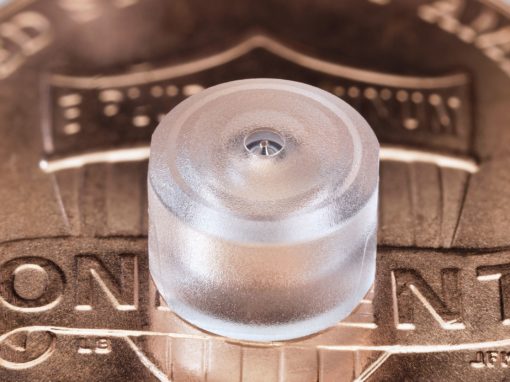

Bring us your toughest medical micro molding challenges including:

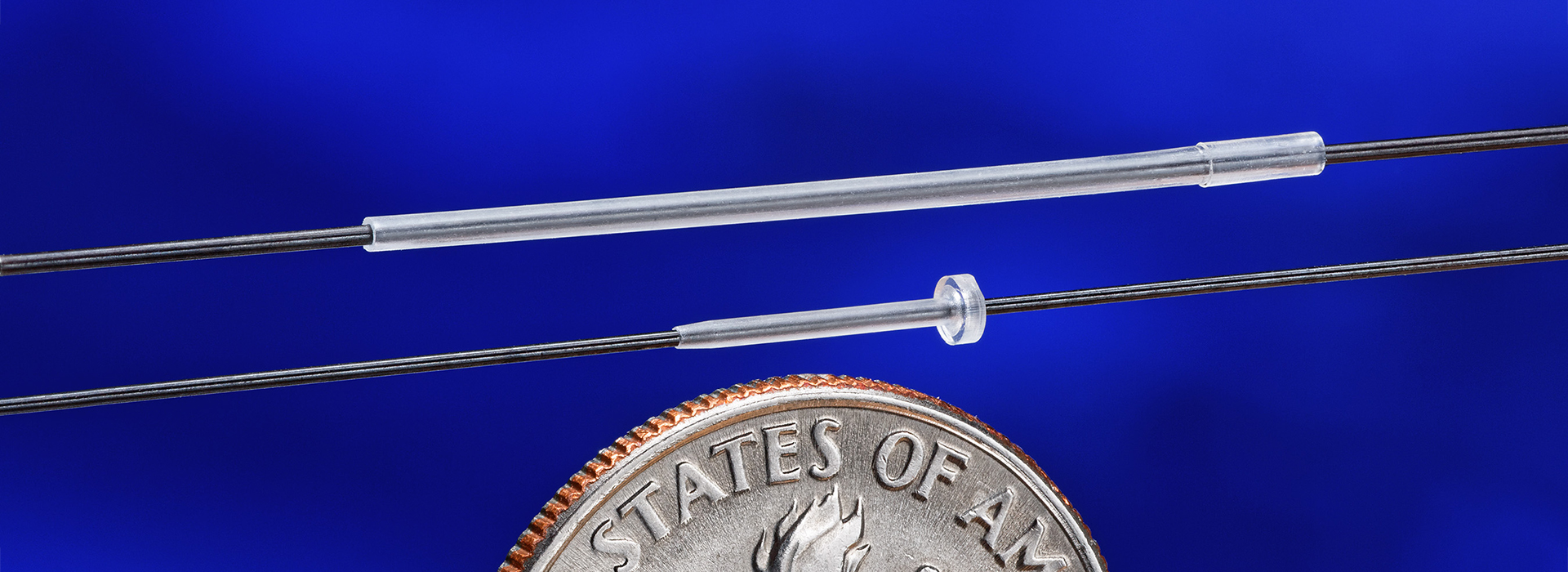

- Bioabsorbable components requiring consistent and minimal post-mold IV loss

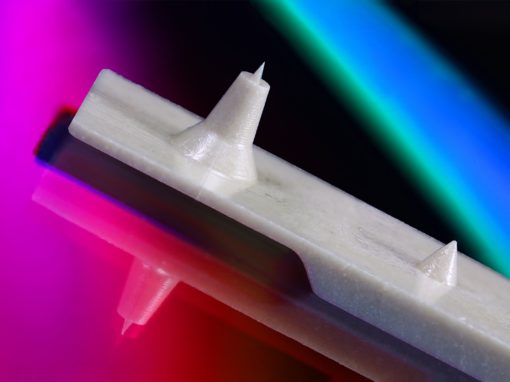

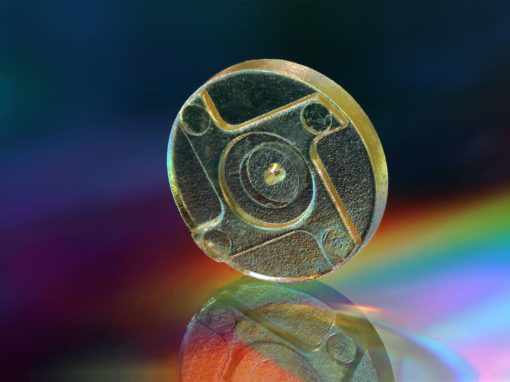

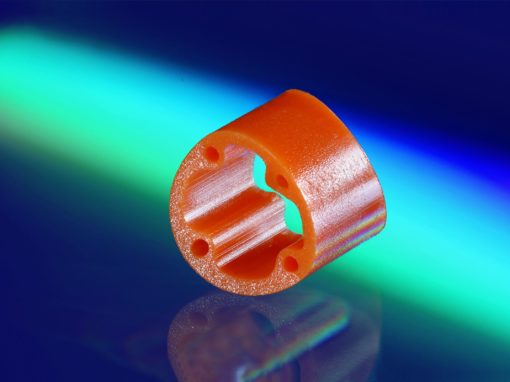

- Drug delivery devices with exact geometries and extremely tight tolerances

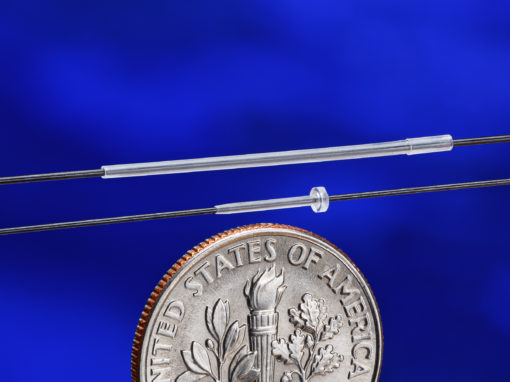

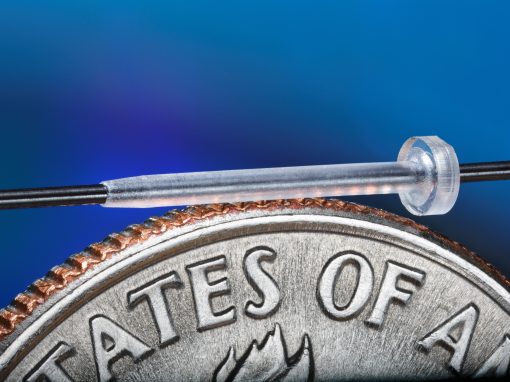

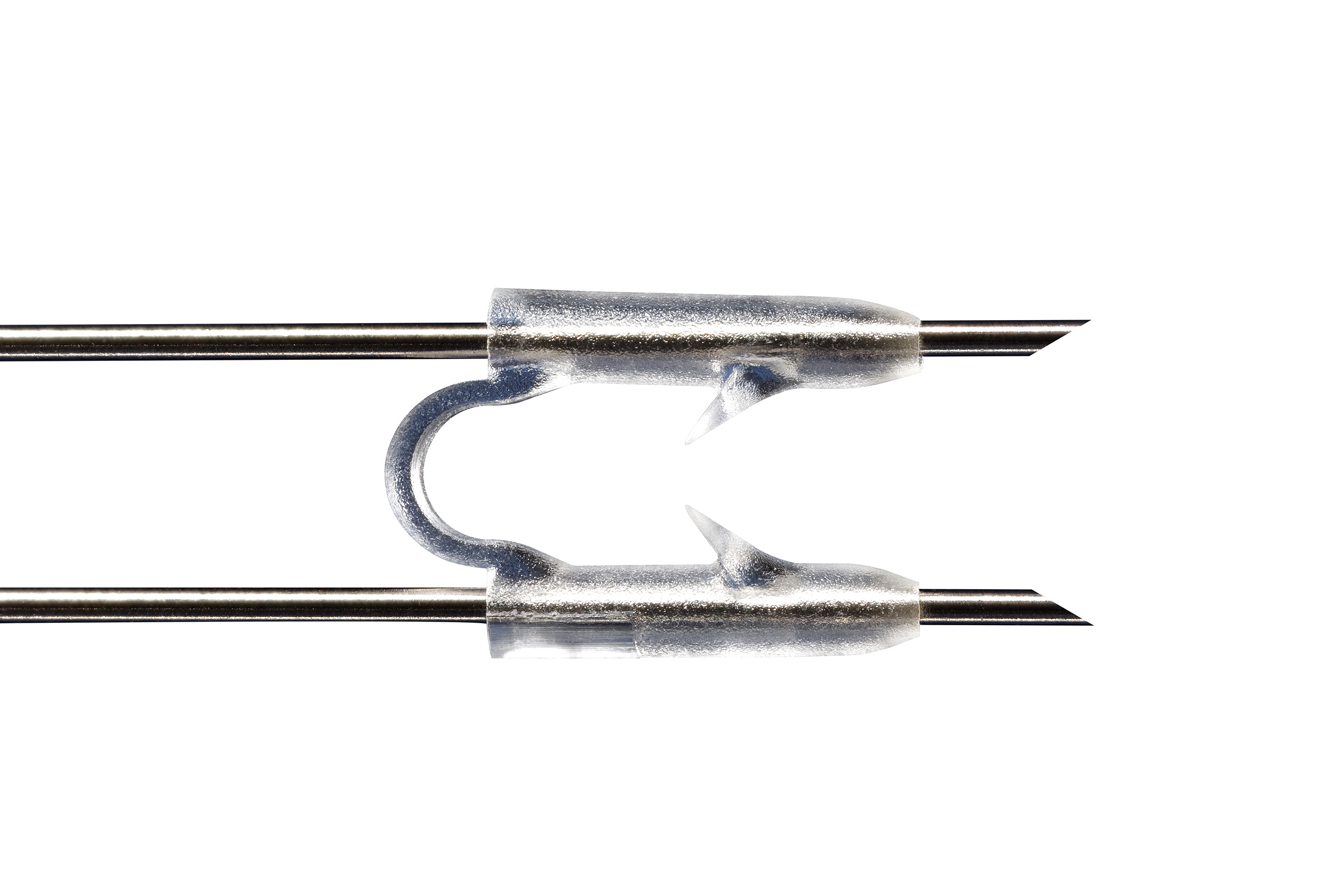

- Overmolded components with micro features and ultra-thin walls

- Medical products with high-aspect ratio flow lengths

Talk to MTD.

We are your single-source supplier that can solve the most complex challenges.

In fact…

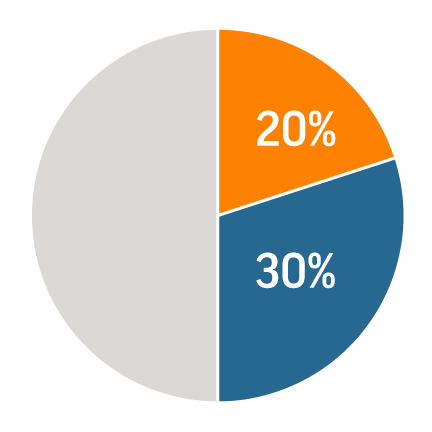

30% are projects that no one else would even attempt or were called “impossible.”

20% of our new projects come to us as “rescues,” or failed attempts by other suppliers.

Talk to us about your challenging project.

Why MTD?

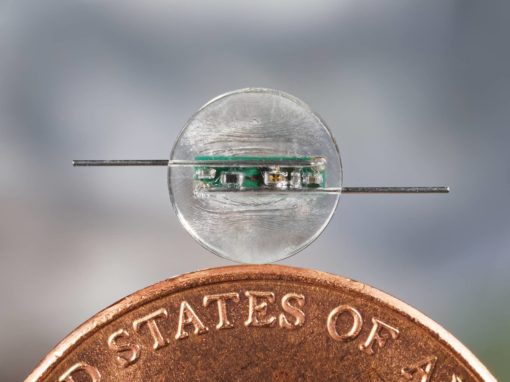

MTD produced a micromolded component that other companies said was impossible. The MTD staff provided us with excellent technical advice and delivered the component on time. The component exceeds our tolerance expectations.

If you can dream it, MTD can make it.

The care MTD takes to characterize the materials in order to develop the most robust process possible while operating within very tight tolerances is second to none. Additionaly, it is clear that the in house tooling capabilities of MTD allow for not only incredibly precise implants, but also allow flexibility and turnaround time that our customers truly value.